100T/D MRF Project

By MSWsorting

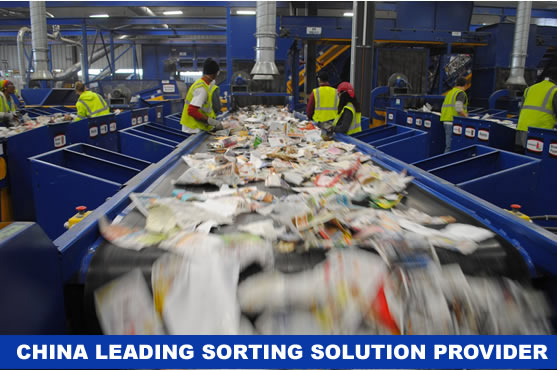

Materials Recovery Facility (MRF) is a specialized plant designed to receive, sort, process, and recover recyclable materials from mixed waste streams. These facilities play a crucial role in waste management systems by separating materials such as paper, cardboard, plastics, metals, and glass for recycling purposes. MRFs utilize various technologies, including conveyor belts, screens, magnets, and optical sorting systems, to efficiently sort and process incoming materials. The recovered recyclables are then baled or otherwise prepared for sale to manufacturers, while any remaining non-recyclable waste is typically sent to landfill or further treatment. MRFs contribute to environmental sustainability by diverting recyclable materials from landfills, conserving natural resources, and reducing the overall environmental impact of waste disposal.

Waste Sorting

For countries with low labor costs, a combination of mechanical and manual sorting can be used, which is a cost-effective waste sorting and recycling solution.

Read More

The artificial intelligence sorting robot with autonomous learning can practice and accumulate sorting data. It can effectively sort various high-value recyclables.

Read More

Optical sorter is a automatic sorting device based on sensors, high-speed ejector valve has large processing capacity. It is a good choice for bulk handling project of waste recycling.

Read MoreChina leading waste sorting plant solutions provider. have had more than 30 years experiences in waste recycling industry. Domestic Market have 10 Million Ton wastes per year recycling by MSWsorting equipmentChina's first waste sorting machine manufacturer and pioneer. many official bodies are our client, it's strict procurement process can prove our product quality and service.

ABOUT US

Export to 20+ countries

50+ Employees

Patent for Invention

Project Cases

Bin feeding systems have good input performance

Waste Conveying Systems OEM design is available

Double Shaft Shredding Systems, output size less than 300mm

Sorting and rycycling iron metal from mixted materials

Eddy-Current Separation can get Copper, Aluminum metals

Ballistic separating systems can sorting 2D and 3D materials

Air Sorting Systems can separating lightweight and heavy materials

Separating oversize waste and undersize food waste

For packing recyclables (plastic and paper)

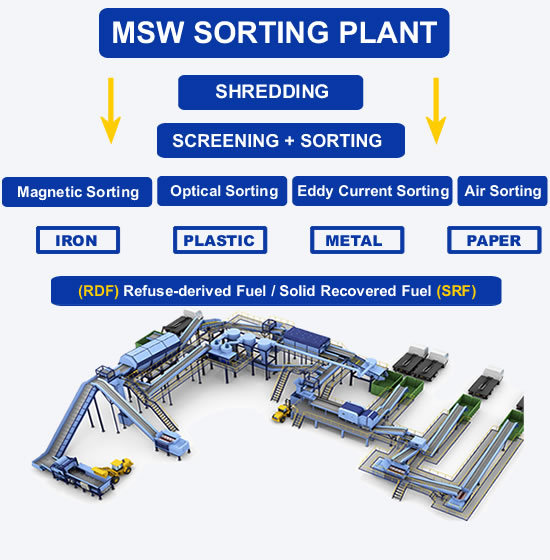

Recycling high-value waste products from municipal solid waste: paper, plastic, iron, copper, aluminum and other non-ferrous metals. If you have higher sorting requirements, our sorting system can add optical sorting systems and Eddy-Current Separation to recycle waste products such as PET bottles, PVC plastic, single material etc.

The composting method for the treatment of domestic waste refers to the method of decomposing organic matter in domestic waste and decomposing it into a stable humus-like soil under the conditions of the biochemistry of microorganisms. It can be divided into two kinds: anaerobic fermentation and aerobic fermentation.

RDF is an abbreviation for Refuse Derived Fuel. It has the characteristics of high calorific value, stable combustion, easy transportation, easy storage, low secondary pollution, and low emission of dioxins. It is widely used in drying engineering and cement. Manufacturing, heating engineering and power generation engineering.

Sorting and Recycling Solution include from waste feeding systems to baling systems

This solutions include composting equipment for food & organic waste except sorting equipment

Provide RDF/SFR making and drying equipment after sorting and recycling sytems