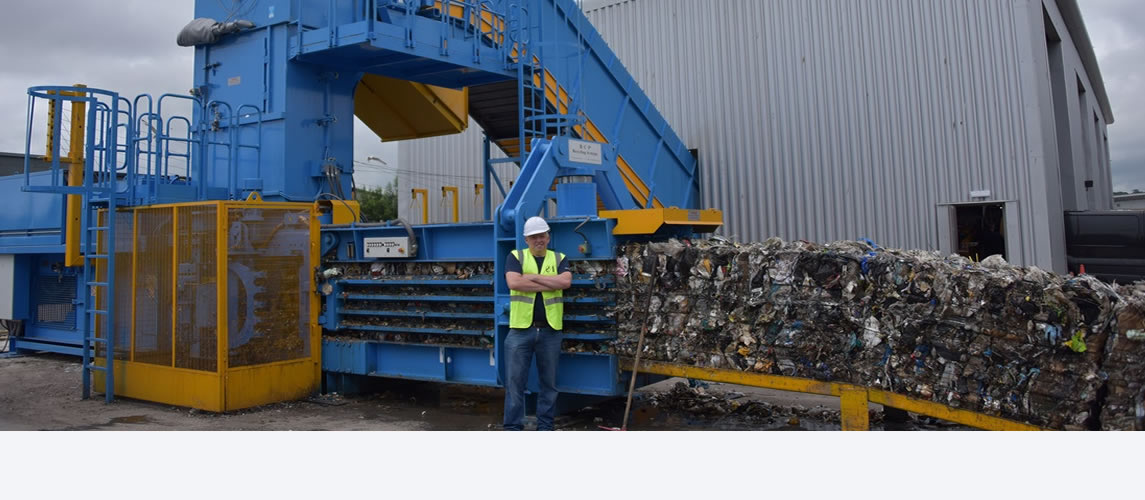

Plastic and Paper Baler

Based on MSWsorting sorting solutions

MUNICIPAL SOLID WASTE SORTING EQUIPMENT

The recyclables are transferred into the baler's metallic hopper by means of a chain conveyor. Once the hopper is full of material, the baler's main piston runs forward and the material is entering the tunnel, thanks to the metallic plate's pressure. The working pressure has been pre-viously set at the desired value. Once the desired bale length is obtained, it is tied automatically with steel wire. completes the full work of stepping up, packing, and pushing out materials through the hydraulic system.

A Plastic and Paper Baler is a powerful industrial machine designed to compress loose recyclable materials, such as plastic bottles, containers, cardboard, and paper, into dense, manageable blocks called bales. This process is a critical step in the recycling and waste management industry. By compacting these materials, the baler significantly reduces their volume, making storage, handling, and transportation far more efficient and cost-effective. The resulting bales are uniform in size and shape, which makes them a standardized commodity that can be easily sold to recycling plants for further processing into new products.

This machine is a cornerstone of any modern Material Recovery Facility (MRF) or recycling center. It transforms bulky, space-consuming piles of sorted recyclables into neat, stackable units. The operation of a baler is typically automated and controlled by a hydraulic system, which provides the immense force needed for compression. Using a baler is not only practical for logistics but also promotes environmental sustainability by ensuring that valuable recyclable materials are efficiently prepared for their next life in the manufacturing cycle, thus supporting the circular economy.

Modern balers are equipped with robust metallic hoppers and feed systems, often integrated with chain conveyors for smooth and continuous material loading. This automation minimizes manual handling and increases operational safety. The core of the machine is its powerful hydraulic piston system, which generates precise and adjustable pressure to compact the waste. The working pressure can be pre-set to optimal levels for different material types, ensuring consistent bale density without damaging the materials inside, whether they are rigid plastics or corrugated cardboard.

Another essential feature is the automatic tying mechanism. Once the compressed material reaches a pre-determined length within the compression chamber or tunnel, the machine automatically binds the bale with steel wires or plastic straps. This secures the bale's shape and integrity. The entire cycle—from feeding and compressing to tying and ejecting the finished bale—is seamlessly managed by the hydraulic and control systems. This integration allows for high throughput, reliability, and minimal operator intervention, making the baler a highly efficient piece of equipment in waste management workflows.

The operation of a waste baler follows a precise, automated cycle to ensure efficiency and safety. The process begins when sorted recyclables, like plastic or paper, are fed into the machine. This is often done using a chain conveyor that transfers the materials directly into the baler's large metallic hopper. The hopper acts as a holding area, gathering a specific volume of loose material. Once the hopper is full, a signal triggers the next phase of the operation. A metallic plate or pusher then guides the material from the hopper into the main compression chamber, known as the tunnel, preparing it for the key compacting stage.

The core action involves the baler's main hydraulic piston. This piston moves forward with tremendous force, compressing the material against a fixed wall inside the tunnel. The hydraulic system's pressure, which is carefully pre-set based on the type of material being processed, ensures effective compaction without over-stressing the machine. As the piston retracts, more material can be added for the next compression cycle, building the bale layer by layer until it reaches the desired length. Finally, an automatic tying system wraps steel wires around the dense block to hold it together. The finished bale is then ejected from the tunnel, ready for storage or shipment.

Plastic and paper balers are indispensable in Material Recovery Facilities (MRFs), where they are used to process streams of sorted consumer and industrial waste. After materials like PET bottles, HDPE containers, aluminum cans, cardboard, and mixed paper are separated by screens, magnets, and optical sorters, they are directed to dedicated balers. Each baler is typically configured for a specific material type to produce clean, high-quality bales that meet market specifications. For instance, a baler processing cardboard will produce bales distinct from one processing clear plastic film, each destined for different recycling markets and remanufacturing processes.

Beyond large-scale MRFs, balers are also widely used in retail settings, distribution centers, manufacturing plants, and institutions like schools and hospitals. These entities generate significant amounts of cardboard and plastic packaging waste. An on-site baler allows them to compact this waste immediately, reducing the frequency of waste pickups, lowering disposal costs, and generating potential revenue from the sale of baled recyclables. This decentralized application demonstrates how baler technology supports waste reduction and resource recovery at the very point where waste is generated, contributing to more sustainable business operations.

The primary benefit of using a baler is the dramatic reduction in the volume of recyclable materials. By compressing loose items into tight bales, businesses and recycling facilities can save a substantial amount of storage space. This space efficiency translates directly into economic advantages, as it reduces the need for large storage areas and decreases the number of transportation trips required to move materials to recycling plants. Furthermore, standardized bales are easier and safer to handle with forklifts or conveyor systems, streamlining warehouse logistics and reducing manual labor risks associated with moving loose, bulky materials.

From an environmental and economic perspective, balers enhance the value of recyclables. Dense, well-formed bales are a preferred raw material for recycling mills because they are consistent and contain minimal contaminants. This often commands a higher market price. Using a baler also promotes a clear and organized waste management system, helping organizations achieve sustainability goals and comply with environmental regulations. By efficiently closing the loop on materials like plastic and paper, balers play a vital role in conserving natural resources, reducing landfill use, and lowering the overall carbon footprint associated with waste management and new material production.

Based on MSWsorting sorting solutions

Based on MSWsorting sorting solutions

Based on MSWsorting sorting solutions

Belt ConveyorManual Sorting Room

For countries with low labor costs, a combination of mechanical and manual sorting can be used, which is a cost-effective waste sorting and recycling solution.

Read More

AI SortingSorting Robot

The artificial intelligence sorting robot with autonomous learning can practice and accumulate sorting data. It can effectively sort various high-value recyclables.

Read More

Optical Sorting

Optical sorter is a automatic sorting device based on sensors, high-speed ejector valve has large processing capacity. It is a good choice for bulk handling project of waste recycling.

Read More