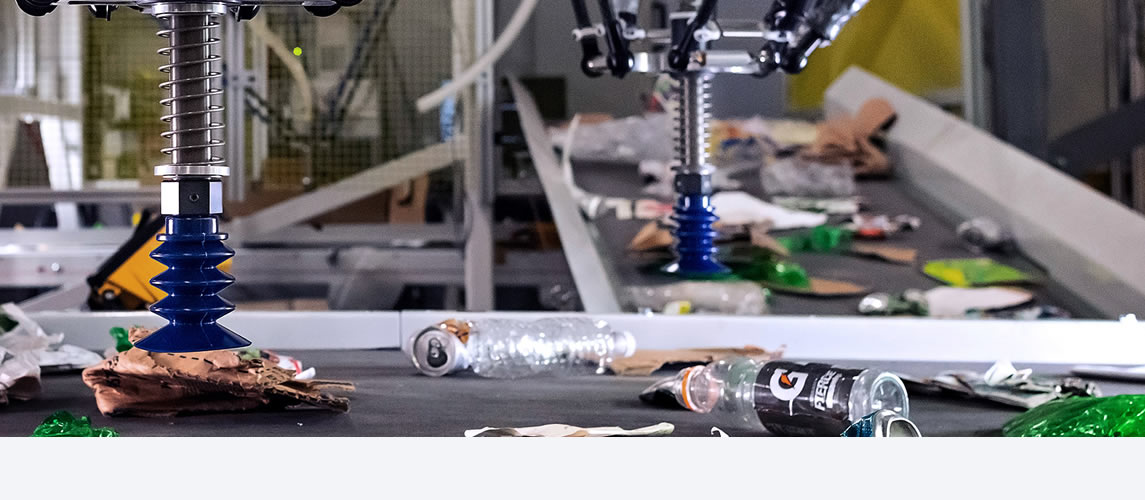

Suck up model sorting robot

Based on MSWsorting sorting solutions

MUNICIPAL SOLID WASTE SORTING EQUIPMENT

First, the visual recognition system uses a camera to scan to identify incoming materials on the conveyor belt. Then, the recognized data can be collected to accumulate a "cloud brain" for the robot's brain. In the early stage, the robot is trained to make the robot's brain recognize these incoming materials and gradually possess human-like autonomous judgment capabilities. Finally, convey the "information" to the robot to quickly identify the recyclables and impurities in the mixed garbage, accurately grab them and put them into the corresponding bins to complete the classification.

The sorting robot is based on artificial intelligence technology, with deep learning, AI algorithms, big data analysis, robot control, cloud brain, multi-sensor fusion and other high-tech equipment.

A sorting robot is an advanced piece of industrial machinery designed to automate the process of separating different types of materials within a waste stream. In essence, it is a robotic arm or system equipped with sophisticated sensors and intelligence that allows it to identify, pick, and place items from a moving conveyor belt into designated categories, such as plastics, metals, paper, and contaminants. This technology represents a significant leap forward from traditional manual sorting or basic mechanical separation methods, bringing precision, speed, and consistency to Material Recovery Facilities (MRFs) and recycling plants. By mimicking and augmenting human decision-making, these robots tackle the complex challenge of modern waste, which often contains a mixture of recyclables that are difficult to separate using conventional screens and magnets alone.

The core of a sorting robot's capability lies in its integration of several high-tech systems. It is built upon a foundation of artificial intelligence, specifically utilizing deep learning algorithms. These algorithms allow the robot to be trained on vast image datasets, enabling its visual recognition system to learn and identify thousands of different material types, brands, and shapes with remarkable accuracy. Furthermore, these robots often employ multi-sensor fusion, combining data from high-resolution cameras, near-infrared (NIR) sensors, and sometimes 3D scanners to gain a comprehensive understanding of each object's material composition, color, and size. This sensory input is processed in real-time to make instantaneous sorting decisions.

Another defining feature is the concept of the "cloud brain" or networked intelligence. Data from every item scanned by robots across a facility—or even across multiple facilities—can be collected and analyzed. This continuous stream of data feeds back into the AI models, allowing them to learn and improve collectively over time. This means the system becomes smarter and more adaptable; it can learn to recognize new packaging materials or adjust its sorting logic based on changing waste compositions without needing to be individually reprogrammed for each new scenario. This combination of real-time robotic control and cloud-based learning creates a powerful, self-optimizing sorting solution.

The operation of a sorting robot is a seamless, high-speed cycle of perception, analysis, and action. The process begins as mixed waste travels on a conveyor belt through the robot's field of view. A high-speed camera system, often paired with spectroscopic sensors, scans each item. This system captures detailed images and gathers data on the object's material signature. This information is instantly transmitted to the robot's onboard computer, where the pre-trained AI model analyzes it. The AI compares the scanned data against its vast learned database to determine the item's material type—for instance, distinguishing between PET plastic, HDPE plastic, aluminum, cardboard, or a non-recyclable contaminant.

Once an item is identified, the system calculates its precise location and trajectory on the belt. Within milliseconds, it sends coordinated commands to a high-speed robotic arm, typically equipped with a versatile gripper or suction cup. The arm swiftly moves to intercept the item, picks it up, and places it into the correct collection chute or bin located beside the conveyor. This entire sequence, from scanning to placement, happens in a fraction of a second, allowing a single robot to perform tens of thousands of picks per hour with consistent accuracy, far surpassing human speed and endurance while working in a dirty and potentially hazardous environment.

Sorting robots are primarily deployed in Material Recovery Facilities (MRFs) to enhance the purity and recovery rates of recyclables from municipal solid waste. They are exceptionally valuable for performing "quality control" sorts on pre-screened waste streams. For example, after bulkier items and fines are removed by screens, a robot can be stationed to pick specific high-value plastics like PET bottles from a mixed plastic stream, or to remove contaminants from a stream of recovered paper. This application is crucial for producing clean, marketable bales of recycled material that meet the strict quality standards demanded by manufacturers.

Beyond traditional MRFs, this technology is finding use in specialized recycling operations. They can be used in electronic waste (e-waste) recycling plants to identify and separate different types of circuit boards, plastics, and valuable metals. In construction and demolition waste facilities, robots can help sort wood, metals, and specific types of plastics from rubble. Their flexibility and programmability also make them suitable for sorting specific items in reverse logistics, such as identifying and separating returned products or packaging in large distribution centers for reuse or recycling, thereby supporting the principles of a circular economy.

The adoption of sorting robots brings substantial operational and economic benefits to waste management and recycling industries. Firstly, they dramatically improve sorting purity and recovery rates. By making precise, data-driven decisions, robots significantly reduce contamination in sorted material bales. This leads to higher-quality recyclables that command better prices in the market and are more desirable for end-users. Increased recovery rates also mean more material is diverted from landfills, directly supporting environmental sustainability goals and helping municipalities and companies meet stringent recycling targets.

From a business perspective, robots offer a compelling solution to chronic challenges like high labor turnover, the difficulty of hiring for repetitive and unattractive jobs, and concerns over worker safety in environments with sharp objects and dust. Robots can operate 24/7 with unwavering consistency, increasing overall plant throughput and operational efficiency. While the initial investment is significant, the long-term benefits include lower labor costs, reduced downtime, and less material loss due to human error. Furthermore, the continuous learning capability of the AI "cloud brain" ensures that the system is a future-proof investment, capable of adapting to new waste streams and regulations, thus protecting and enhancing the value of the recycling operation over time.

Based on MSWsorting sorting solutions

Based on MSWsorting sorting solutions

Based on MSWsorting sorting solutions

Belt ConveyorManual Sorting Room

For countries with low labor costs, a combination of mechanical and manual sorting can be used, which is a cost-effective waste sorting and recycling solution.

Read More

AI SortingSorting Robot

The artificial intelligence sorting robot with autonomous learning can practice and accumulate sorting data. It can effectively sort various high-value recyclables.

Read More

Optical Sorting

Optical sorter is a automatic sorting device based on sensors, high-speed ejector valve has large processing capacity. It is a good choice for bulk handling project of waste recycling.

Read More