Mechanical Biological Treatment (MBT)

LEADING WASTE SORTING AND RECYCLING EQUIPMENTS PROVIDER

What is MBT (Mechanical-Biological Treatment)?

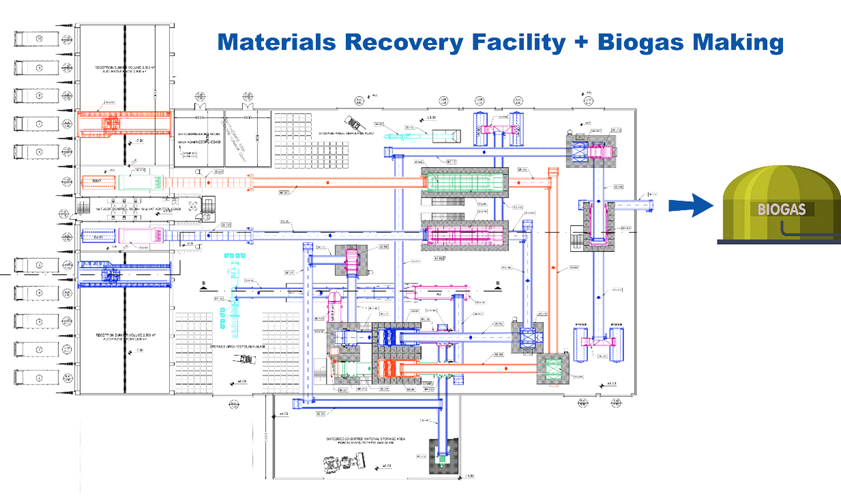

Mechanical-Biological Treatment (MBT) represents a significant evolution in sustainable waste management. It can be best understood as an advanced, integrated system that combines the resource recovery capabilities of a Materials Recovery Facility (MRF) with the biological stabilization and valorization of the organic waste fraction.

While a standard MRF focuses primarily on extracting high-value recyclables (metals, plastics, paper, etc.) and often treats the separated organic waste as a residue, an MBT plant is designed to process the entire mixed waste stream with a dual mission: recovery and stabilization. The primary goals are to:

Maximize the diversion of waste from landfill.

Recover recyclable materials as marketable commodities.

Biologically treat the organic fraction to reduce its mass, volume, and environmental impact (such as odor, leachate, and greenhouse gas emissions).

Transform the treated outputs into useful products like compost, biogas, or Solid Recovered Fuel (SRF)/Refuse-Derived Fuel (RDF).

MBT is particularly crucial for regions without source separation of organic waste. It addresses the challenge of wet, mixed municipal solid waste by systematically handling both its "dry" (recyclable) and "wet" (organic) components, turning a disposal problem into a resource opportunity. It is the cornerstone of a zero-waste-to-landfill strategy for untreated municipal solid waste.

How Does a Mechanical-Biological Treatment System Work?

An MBT plant operates in two distinct but interconnected stages: the Mechanical (M) and the Biological (B) stages. The principle is to first separate the waste into different streams mechanically and then biologically treat the organic-rich fraction.

Stage 1: Mechanical Separation & Processing (The "MRF" Core)

This initial stage is similar to a "dirty" MRF process but is optimized to prepare a high-organic feedstock for the subsequent biological stage.

Reception & Pre-processing: Incoming mixed waste is tipped, and large, non-processible items are removed. Bag openers/breakers liberate the waste.

Primary Screening: The waste passes through screens (trommels, disc screens) to remove fine, highly putrescible organic material and inert fines (soil, glass). This "undersize" fraction is rich in organic matter and moisture and is sent to the biological treatment stage.

Resource Recovery Line: The "oversize" fraction undergoes further processing to recover valuables:

Ferrous Metals: Removed by magnetic separators.

Non-Ferrous Metals: Extracted via eddy current separators.

High-Grade Recyclables: Optical sorters (NIR/AI) and other separators recover specific plastics (PET, HDPE), paper/cardboard, and other dry recyclables, which are then baled for sale.

High-Calorific Fraction: The remaining, largely non-recyclable dry materials (mixed plastics, textiles, wood, paper) can be shredded and refined to produce a high-quality SRF/RDF.

Stage 2: Biological Treatment (The "Plus" in MRF+)

The organic-rich undersize from Stage 1 is biologically stabilized. Two main pathways exist:

Aerobic Biological Treatment (Composting/Bio-drying):

Composting: The organic material is placed in windrows or enclosed tunnels. Under controlled aeration, microorganisms break down the biodegradable matter, reducing volume and producing a stabilized compost-like output. This output often requires further screening to remove inert contaminants and is typically used for non-agricultural purposes (landscaping, landfill cover).

Bio-drying: Air is forced through the organic mass primarily to evaporate water, using microbial heat. The goal is not decomposition but rapid drying to create a stable, high-calorific fraction suitable for SRF/RDF production.

Anaerobic Digestion (AD): The organic slurry is fed into sealed, oxygen-free digesters. Microorganisms break down the material, producing biogas (a mixture of methane and CO2) which can be used to generate electricity and heat. The remaining digestate can be further composted or used as a soil amendment.

The final outputs of an MBT plant are thus: Recyclables, SRF/RDF, Biogas/Compost, and a minimal amountof inert residues for landfill.

Key Equipment and Installations in an MBT Plant

An MBT facility integrates the full suite of MRF equipment with specialized biological treatment installations.

A. Mechanical Separation Line Equipment:

As previously detailed in MRF section: Bag Openers, Trommel/Disc/Vibrating Screens, Magnetic Separators, Eddy Current Separators, Optical Sorters (NIR, AI), Ballistic Separators, Shredders, and Baling Presses.

Refinement for MBT: Equipment is often heavy-duty to handle the challenging mixed waste, and screen sizes are carefully chosen to optimize the split between the organic-rich unders and the dry overs for fuel production.

B. Biological Treatment Installations:

For Aerobic Treatment:

Bio-Hall/Enclosed Hall: A large, ventilated building to contain the process and control emissions.

Turners/Windrow Turners: Mobile machines that regularly aerate and mix long piles (windrows) of organic material.

Aerated Static Pile or Tunnel Systems: Systems where air is actively blown or sucked through static piles of material, offering greater process control and odor management. Tunnels are fully enclosed reactors.

Biofilters: Essential for treating the exhaust air from the biological halls, using a bed of organic material to absorb and biologically degrade odors.

For Anaerobic Digestion:

Pre-treatment/Pulpification Units: Prepare the organic slurry (often called "pulp") for digestion.

Digester Tanks: Large, heated, and sealed tanks where the anaerobic process occurs. They can be vertical or horizontal.

Gas Storage & CHP Unit: Biogas is stored in tanks and then fed into a Combined Heat and Power (CHP) unit to generate renewable energy.

Digestate Dewatering & Processing: Equipment like centrifuges or screw presses separate the digestate into a liquid fraction and a solid fraction, which may be composted further.

Why Choose MSWsortingfor Your MBT Project?

Designing a successful MBT plant is exponentially more complex than a standard MRF, as it involves the intricate integration of two very different technological processes. The stakes for performance, reliability, and economic viability are exceptionally high. MSWsorting is uniquely positioned to be your ideal partner for this challenge.

Our 30-year global waste composition database is even more critical for MBT design. The efficiency of the biological stage depends entirely on the quality and characteristics of the organic fraction we feed it. Our data allows us to predict not just the volume of organics, but also its moisture content, C/N ratio, and biodegradability, enabling us to engineer a biological process that is precisely calibrated for your local waste.

We offer true integrated design. Unlike companies that may specialize only in mechanical sorting or only in biological systems, we provide a holistic, turnkey solution. Our engineers design the mechanical pre-treatment stage with the explicit goal of creating the optimal feedstock for the subsequent biological stage, whether it's digestion or composting. This seamless integration maximizes biogas yield, compost stability, or SRF quality.

Furthermore, we deliver future-proof and flexible solutions. We understand that energy markets and policy priorities evolve. Our MBT designs can be modular, allowing clients to start with a composting line and later integrate an anaerobic digestion module, or to adjust the SRF production line based on market demand. With MSWsorting, you invest in an adaptive resource recovery hub, not just a waste processing plant.

MBT Solutions: Integrated Pathways for Maximum Resource Recovery

Our MBT solutions are not off-the-shelf plants but carefully engineered systems that define the optimal resource recovery pathway based on local conditions, regulations, and economic drivers. We typically design three core solution types:

The Material & Organic Recovery MBT: This solution focuses on maximizing the extraction of high-purity recyclables and producing a high-quality, stabilized compost or soil amendment. It involves intensive mechanical sorting followed by extended aerobic composting (often in enclosed tunnels for superior odor and process control). It is ideal for regions prioritizing landfill diversion and soil health, with markets for compost.

The Energy & Material Recovery MBT (with AD): This is the most resource-efficient configuration. The mechanical stage recovers recyclables and prepares a clean organic pulp. This pulp is fed into an anaerobic digestion plant to produce renewable biogas (for grid injection or CHP) and digestate. The system maximizes energy recovery from the organic fraction while also capturing recyclables. It offers the best greenhouse gas reduction profile.

The SRF Production & Stabilization MBT: This solution is geared towards replacing fossil fuels in industry (e.g., cement kilns, power plants). The mechanical stage is optimized to produce a high-calorific, low-chlorine SRF from the dry fraction. The wet organic fraction undergoes bio-drying—a rapid aerobic process that uses microbial heat to evaporate water, resulting in a dry, stable material that can be blended into the SRF stream, boosting yield and fuel quality. This solution maximizes landfill diversion and provides a direct substitute for coal.

At MSWsorting, we conduct a thorough feasibility study to recommend the perfect blend of these pathways. Our MBT solutions ensure that every component of mixed waste is assigned a destination higher than landfill, transforming municipal solid waste into a reliable stream of materials, energy, and fuel.

ADVANTAGE

WHY CHOOSE MSWsorting

Focus on waste sorting technology more than 30 years

Research & Development

Professional waste sorting R&D team

Engineering Design

Multifarious engineering design Services

High Quality & Services

Stable operation and good service

Focus on waste recycling and sorting technology innovation. the pursuit of comprehensive, professional, timely and enthusiastic service to win the trust of customers, growing together with customers.

MSWsorting relies on the technical team who from University of Science and Technology of China. and based on himself research and manufacturing experiences accumulated over the past 30 years. Created China's first waste sorting technology research center.