Materials Recovery Facility (MRF)

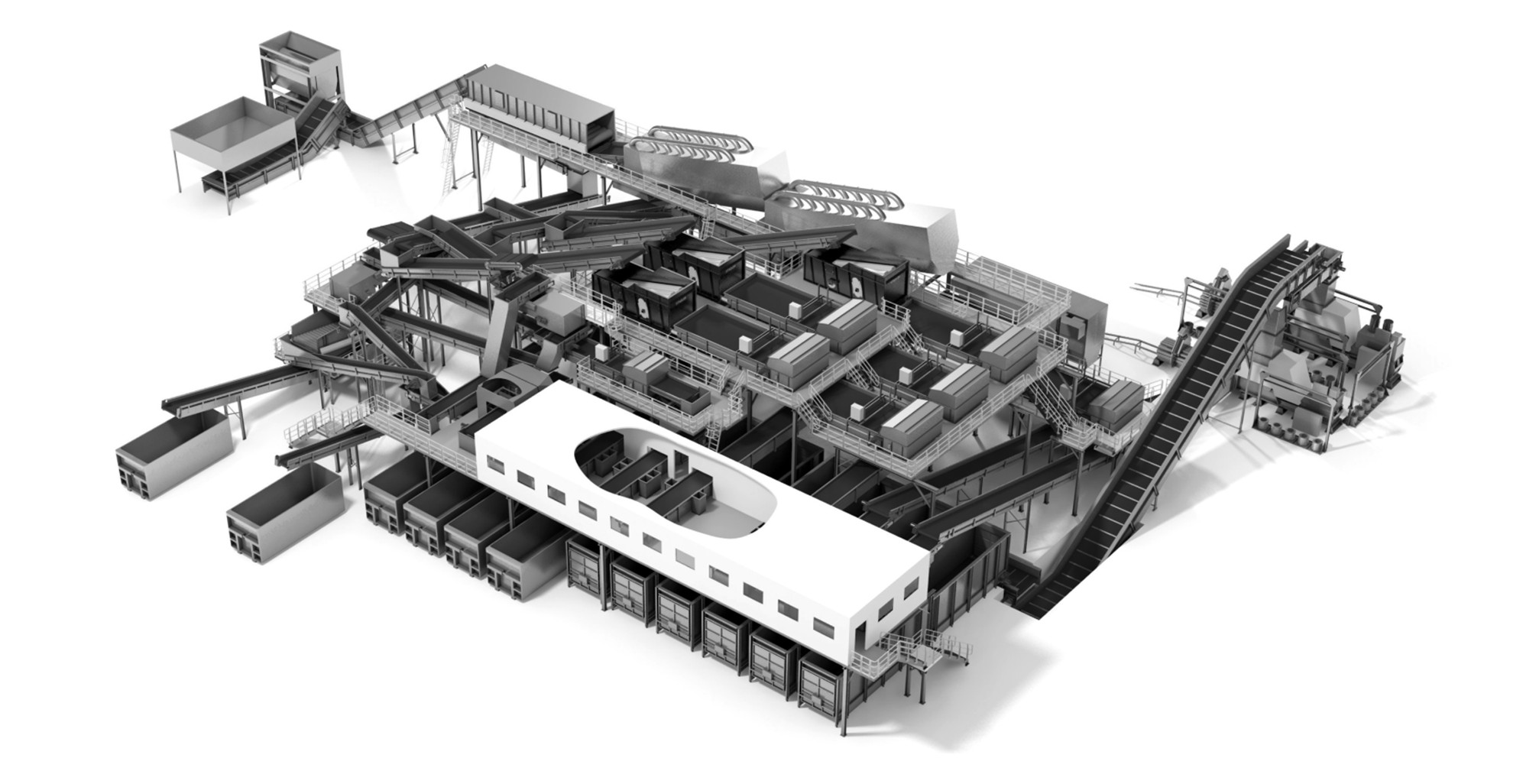

Leading Waste Recycling Equipment and Integrated Materials Recovery Facilities (MRFs)

What is MRF (Materials Recovery Facility)?

Materials Recovery Facility (MRF), often pronounced "murf," is a specialized plant designed to systematically sort, separate, and prepare recyclable materials from mixed waste streams for sale to end-market manufacturers. Think of it as a high-tech recycling factory where commingled recyclables or mixed municipal solid waste (MSW) are transformed into clean, marketable commodities like metals, plastics, paper, cardboard, and glass.

The core mission of an MRF is to maximize resource recovery, divert waste from landfills, and support the circular economy by supplying quality raw materials back to industry. MRFs play a critical role in modern waste management infrastructure, bridging the gap between collection systems and recycling markets.

There are generally two types of MRFs:

Clean MRFs: Process source-separated recyclables (from curbside recycling bins) that are relatively free of organic contaminants.

Dirty MRFs (or Mixed Waste MRFs): Process mixed municipal solid waste where recyclables are commingled with organic waste (like food scraps) and other non-recyclables. This type requires a more complex process, often starting with the removal of organic materials.

The effectiveness of an MRF is directly tied to the composition of the incoming waste, which varies drastically by region, culture, and local legislation. A facility designed for efficiently sorted dry waste in one country would be ill-suited for handling untreated mixed waste with high organic content in another. Therefore, deep understanding of local waste characteristics is the foundation of any successful MRF operation.

How Does a Materials Recovery Facility Work?

The operation of an MRF is a sequential, multi-stage process combining mechanical and technological systems. The workflow differs significantly based on whether the input is source-separated ("clean") or mixed ("dirty") waste. Here’s a breakdown of the principle and typical stages:

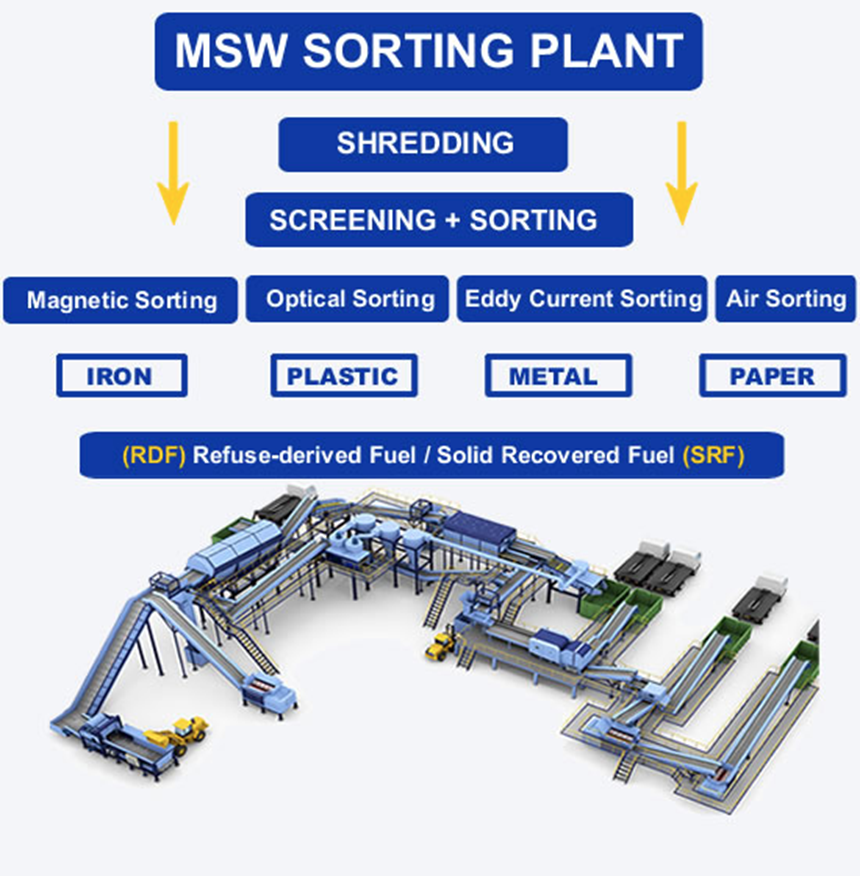

A. For Mixed Waste (Dirty MRF – "Wet" Process):

This process is necessary when waste contains a high percentage of organic matter (typically 40-60%).

Pre-Sorting & Bag Opening: Incoming mixed waste may first pass through a pre-sort station to remove large, hazardous, or non-processible items. An automated bag opener then breaks open trash bags to liberate the materials.

Organic Waste Removal (Critical First Step): The heart of the "wet" process. The waste is fed onto screening equipment such as Trommel Screens (rotating drums with holes) or Disc Screens. These separate smaller, wet organic particles and fines (e.g., food waste, soil) from larger, drier recyclables. The removed organic fraction can be sent for composting or anaerobic digestion.

Size & Shape Sorting: The remaining "dry" stream undergoes further screening (e.g., vibrating screens, ballistic separators) to separate flat materials (like paper and cardboard) from round or bulky items (like containers).

Ferrous Metal Recovery: Powerful overhead Magnetic Separators pull out ferrous metals (iron, steel) from the conveyor belts.

2D/3D Separation & Optical Sorting: A key stage. Ballistic Separators or air classifiers split 2D materials (paper, film) from 3D materials (containers, bottles). These streams then pass by a series of advanced Optical Sorters (NIR - Near-Infrared, AI-powered VIS). These sensors identify material types by their optical signature (e.g., PET plastic, HDPE plastic, aluminum, paper grades) and use precisely targeted air jets to eject them into designated bunkers.

Non-Ferrous Metal Recovery: An Eddy Current Separator induces a magnetic field to repel non-ferrous metals (aluminum, copper), separating them from the remaining waste stream.

Quality Control & Baling: Sorted materials undergo final manual or automated quality checks to remove contaminants. Each clean material is then fed into a Baler, which compresses it into dense, transportable bales ready for shipment to recycling markets.

B. For Source-Separated Recyclables (Clean MRF – "Dry" Process):

This is a more streamlined version. The process typically starts at Stage 4 or 5 above, omitting the initial organic removal steps, as the input is presumed to be relatively clean and dry. The focus is on high-precision sorting of recyclables from minor contaminants.

Throughout both processes, dust collection, odor control, and worker safety systems are integral to the facility's operation.

Key Equipment in an MRF

A modern MRF is an orchestra of specialized machinery, each playing a critical role. Here are the main components:

Bag Openers/Flail Mills: These machines aggressively tear open plastic bags and sacks, releasing the enclosed materials for sorting. They are essential for liberating waste in mixed streams.

Screening Equipment:

Trommel Screens: Large, rotating cylindrical drums with sized holes. They separate materials based on size; smaller items (organics, fines) fall through the holes, while larger items travel to the end.

Disc Screens: A series of rotating shafts with discs. The gap between discs allows smaller materials to drop through, separating them from larger ones. Excellent for separating containers from paper.

Vibrating Screens: Used for sizing and de-dusting, often as a primary screen for removing fine organic matter.

Optical Sorters: The brains of the modern MRF.

NIR Sorter (Near-Infrared): Use infrared light to identify materials based on their molecular composition. They can distinguish between different polymer types (PET, HDPE, PP) and paper grades.

AI Sorter (Artificial Intelligence/Visual): Use high-resolution cameras and machine learning algorithms to identify materials by color, shape, texture, and even labels. They are incredibly adaptive and can learn to sort complex items.

Magnetic Separators: Typically overhead drum magnets or magnetic head pulleys that automatically and continuously extract ferrous metals (tin cans, steel scrap) from the fast-moving waste stream.

Eddy Current Separators: Use a rapidly alternating magnetic field to induce electrical currents in non-ferrous metals (like aluminum), creating a repulsive force that ejects them from the conveyor belt.

Ballistic/Air Separators: Use a combination of vibration and air flow to separate lightweight, flat materials (2D like paper) from heavier, round, or bulky items (3D like containers).

Baling Presses: The final step for recovered materials. They compress sorted paper, cardboard, plastics, and metals into tight, uniform bales, optimizing logistics and market value.

Why Choose MSWsorting?

Selecting the right partner to design and equip your MRF is a decisive factor in its long-term economic and environmental success. At MSWsorting, we bring three decades of dedicated innovation and unmatched global expertise to the table.

Our primary differentiator is our proprietary global waste composition database. For over 30 years, we have rigorously analyzed MSW characteristics from hundreds of cities worldwide. We understand that waste from Southeast Asia differs fundamentally from waste in North America or Europe, not just in volume, but in moisture content, calorific value, organic fraction, and the types of plastics and packaging used. This data-driven insight allows us to move beyond generic solutions.

We design truly customized MRF systems engineered for your specific waste stream. Whether you are handling pre-sorted dry recyclables or challenging mixed waste with high organic content, our process flows and equipment selection are optimized to maximize your recovery rates, purity of output, and overall operational efficiency.

Furthermore, we provide end-to-end partnership. From initial waste audit and feasibility studies through detailed engineering, equipment supply, installation supervision, and operational training, we ensure your facility is built on a foundation of knowledge and is equipped with robust, state-of-the-art technology. We don't just sell machines; we deliver performance-engineered recycling solutions that guarantee a higher return on investment and a greater positive impact for your community and our planet.

MRF Solutions: A Tailored Approach for Every Project

There is no universal "one-size-fits-all" MRF solution. A successful project begins with a deep diagnostic analysis of the local waste stream, collection system, regulatory environment, and market opportunities for recyclables.

At MSWsorting, our solution philosophy is built on customization:

For Regions with Advanced Source Separation: We design high-efficiency "Clean MRF" solutions. These systems focus on advanced optical sorting, gentle handling to preserve material quality, and high-speed automation to process large volumes of commingled recyclables (paper, plastics, metals, glass) with minimal contamination. The goal is to produce premium-grade bales that command the best market prices.

For Regions with Mixed Waste Collection: We engineer robust "Dirty MRF" or Mixed Waste Processing solutions. These facilities are designed to handle the full spectrum of MSW. The initial focus is on the efficient removal and potential valorization of the organic fraction (using screens and digesters/composting). The remaining dry fraction is then processed through a cascade of sorting technologies to recover all possible valuables. This approach significantly reduces landfill dependency and can include refuse-derived fuel (RDF) production from non-recyclable residues.

Hybrid and Future-Proof Designs: We also create flexible facilities that can adapt to changing waste policies. For example, a MRF can be designed to process mixed waste today but be easily adapted to handle source-separated streams in the future as public education improves.

Our MRF solutions integrate not only hardware but also intelligent control systems, data analytics for real-time monitoring of material flows and equipment performance, and comprehensive training packages. We deliver turnkey systems that are durable, efficient, and designed to become a cornerstone of your community's sustainable waste management strategy for decades to come.

ADVANTAGE

WHY CHOOSE MSWsorting

Focus on waste sorting technology more than 30 years

Research & Development

Professional waste sorting R&D team

Engineering Design

Multifarious engineering design Services

High Quality & Services

Stable operation and good service

Focus on waste recycling and sorting technology innovation. the pursuit of comprehensive, professional, timely and enthusiastic service to win the trust of customers, growing together with customers.

MSWsorting relies on the technical team who from University of Science and Technology of China. and based on himself research and manufacturing experiences accumulated over the past 30 years. Created China's first waste sorting technology research center.