Construction Waste Treatment

LEADING WASTE SORTING AND RECYCLING EQUIPMENTS PROVIDER

What is C&D Waste Treatment?

Construction and Demolition (C&D) Waste Treatment refers to the systematic process of collecting, sorting, processing, and converting waste generated from construction, renovation, demolition, and land-clearing activities into reusable materials and resources. Unlike mixed municipal solid waste, C&D waste primarily consists of inert, heavy materials like concrete, bricks, wood, metals, drywall, and asphalt, along with secondary streams like packaging and bulky items.

Modern C&D Waste Treatment goes beyond simple landfilling or basic crushing. It is a sophisticated resource recovery operation designed to achieve near-complete material circulation. The goal is to transform what was once considered debris into valuable commodities, thereby conserving natural resources, reducing landfill dependency, lowering carbon emissions from virgin material extraction, and creating economic value from waste. A state-of-the-art C&D treatment facility acts as a recycling hub, ensuring materials like concrete are reborn as new construction products, metals re-enter the manufacturing cycle, and combustible fractions contribute to energy recovery, striving for over 95% resource recovery and 100% diversion from landfill.

The Principles of C&D Waste Treatment

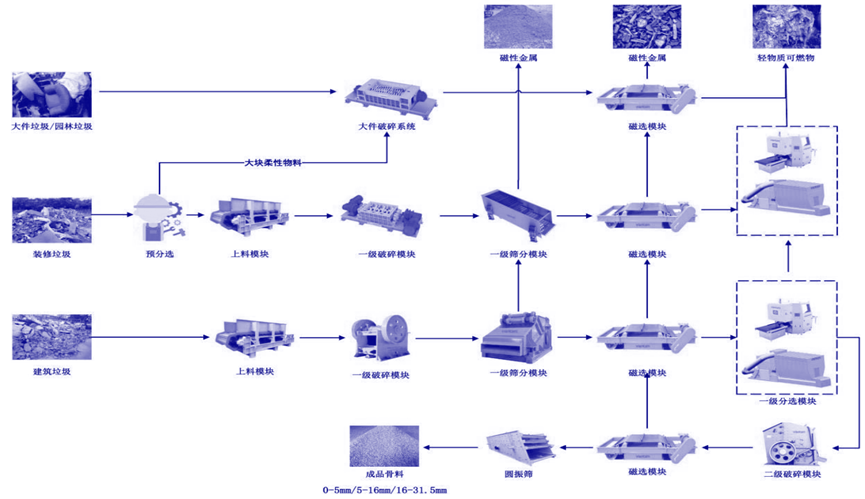

The underlying principle of effective C&D Waste Treatment is "separation before size reduction, and purification after." The process is engineered to sequentially isolate different material fractions based on their physical properties—size, density, magnetic susceptibility, and visual characteristics—to produce clean, marketable outputs. The technical philosophy revolves around a multi-stage, modular approach:

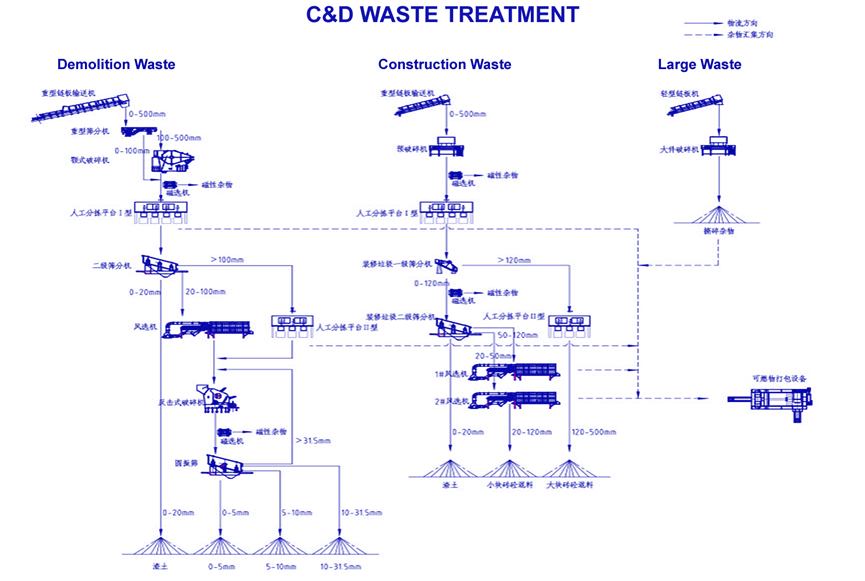

Pre-sorting & Decontamination: Incoming mixed C&D waste is first inspected for hazardous materials (asbestos, chemicals) and oversized items. Manual or mechanical pre-sorting removes contaminants and non-processible waste. Bulky waste (like furniture) is often directed to a dedicated dismantling line.

Size Reduction via Multi-Stage Crushing: The core waste stream undergoes primary and often secondary crushing using robust crushers (like jaw crushers) and impactors. The objective is to liberate bonded materials (metal from concrete) and reduce everything to a manageable, uniform size for efficient sorting.

Multi-Level Separation & Classification: This is the heart of the process. A cascade of separation technologies is employed:

Ferrous Recovery: Powerful overhead magnets extract all ferrous metals.

Size Screening: Vibrating screens or trommels separate materials into different size fractions (oversize for re-crushing, mid-size for aggregate, fines).

Air Classification (Wind Sifting): A critical step where controlled air streams separate light fractions (plastics, paper, wood, insulation) from heavy fractions (concrete, bricks, stones). This is essential for producing clean aggregates.

Advanced Sorting: Eddy Current Separators recover non-ferrous metals (aluminum, copper). AI-Powered Optical Sorters use cameras and machine learning to identify and remove specific contaminants (like wood from aggregate or PVC) or to sort colored glass and plastics, achieving unprecedented purity.

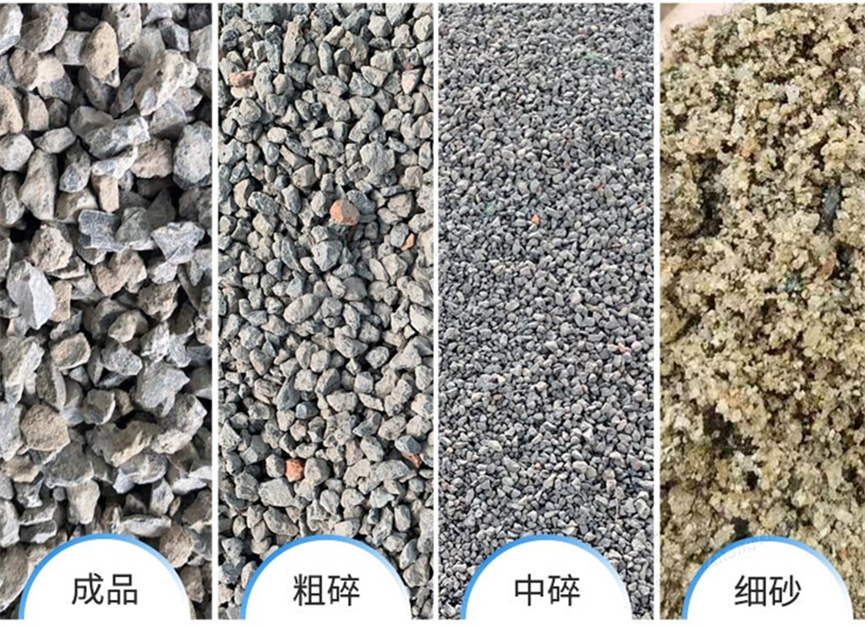

Output Refinement: The separated heavy fraction is further screened to produce precisely graded recycled aggregates (0-5mm sand, 5-20mm gravel). The light fraction is processed for energy recovery. Metals are baled for recycling.

Key Equipment and Installations in a C&D Treatment Plant

A modern C&D plant is an integrated chain of heavy-duty and high-precision machinery:

Feeding & Pre-Sorting Equipment: Includes heavy-duty excavators with sorting grapples, feed hoppers with grizzly screens to remove fines, and manual picking stations or robotic arms for initial contamination removal.

Crushing Systems: Primary Crushers (Jaw Crushers) handle the initial size reduction of large concrete slabs and rubble. Secondary Impact Crushers or Cone Crushers further reduce the material and improve the cubical shape of the aggregate.

Screening Units: Heavy-Duty Vibrating Screens are workhorses for sizing separation. Trommel Screens are excellent for handling dirty material and separating fines. Multiple decks allow for the simultaneous production of several aggregate grades.

Separation & Sorting Technology:

Suspended Plate Magnets & Magnetic Drum Separators: For continuous, automated ferrous metal recovery.

Air Classifiers / Wind Shifters: Utilize adjustable fan speeds and airflows to achieve highly efficient separation of light materials (wood, plastic, paper) from heavy aggregates, crucial for product quality.

Eddy Current Separators: Essential for recovering valuable non-ferrous metals from the waste stream.

AI-Based Optical Sorters: The technological forefront. These systems use high-resolution cameras and artificial intelligence to recognize materials by color, shape, and texture. They can eject specific impurities from conveyor belts with pinpoint accuracy, ensuring the highest purity of final aggregates and sorted fractions.

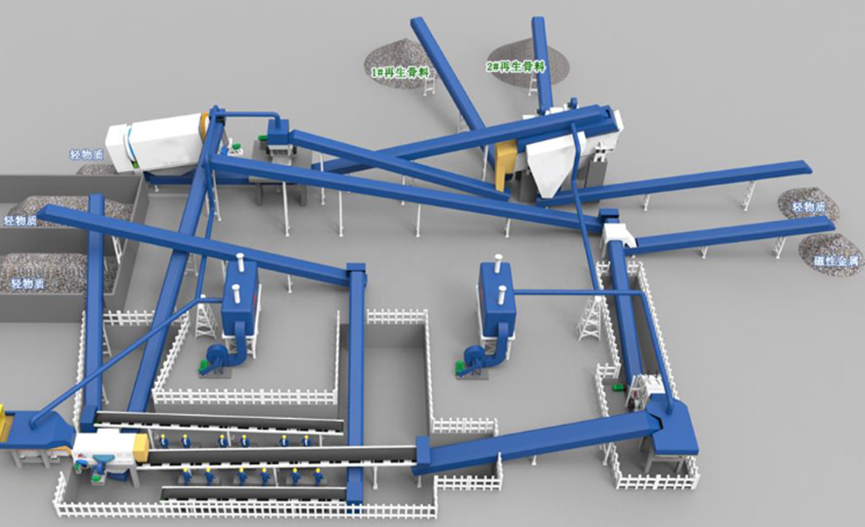

Material Handling & Storage: A network of conveyor belts, stockpilers, and finished product bunkers with automated load-out systems.

Why Choose MSWsortingfor C&D Waste Treatment?

While MSWsortingis rooted in MSW processing, our core expertise in material characterization, separation physics, and system integration translates powerfully into the C&D sector. We approach C&D not just as crushing, but as precision material recovery. Our global database of material streams now includes extensive C&D waste profiles, allowing us to design systems optimized for your local mix of concrete, wood, metals, and contaminants.

Our key advantage is delivering "Plant-as-a-Product" — a fully optimized, performance-guaranteed system. We don't just sell individual machines; we engineer the entire material flow. Our proprietary modular design philosophy allows for the intelligent integration of separate processing lines for demolition waste, renovation waste, and bulky waste that share a central crushing and sorting core. This maximizes flexibility, minimizes footprint, and reduces capital and operational costs. Furthermore, our integration of AI optical sorting sets us apart, enabling our plants to produce cleaner, higher-value recycled aggregates that meet strict specifications for concrete production, a capability few traditional crushing plants can match.

C&D Waste Treatment Solutions

MSWsorting offers scalable, turnkey solutions designed for varying volumes and material compositions:

High-Volume Demolition & Inert Waste Recycling Plant: This solution focuses on processing clean demolition concrete, bricks, and asphalt. It features heavy-duty crushing, multi-stage screening, and magnetic separation to produce high-quality, certified recycled aggregates for road base, drainage, and new concrete. Air classification ensures low contaminant levels.

Integrated Mixed C&D & Bulky Waste Resource Recovery Center: Our flagship, most comprehensive solution. It incorporates three synergistic modules:

A Demolition Waste Line for heavy inert processing.

A Renovation & Mixed Waste Line with advanced air classification and AI sorting to handle complex mixes of wood, drywall, metals, and plastics.

A Bulky Waste Dismantling Line for furniture and fixtures.

All modules feed into a shared crushing and final sorting hub. Outputs include: premium recycled aggregates, cleaned wood chips for biofuel, ferrous & non-ferrous metal bales, a densified RDF fraction from light combustibles, and inert fines for cover material. This system aims for >98% landfill diversion.Mobile / Semi-Mobile C&D Recycling Unit: A flexible solution for remote sites or temporary projects. This system typically includes a mobile jaw crusher, screen, and magnetic separator, allowing for on-site processing to reduce transportation costs and produce aggregate for immediate reuse on the same project.

ADVANTAGE

WHY CHOOSE MSWsorting

Focus on waste sorting technology more than 30 years

Research & Development

Professional waste sorting R&D team

Engineering Design

Multifarious engineering design Services

High Quality & Services

Stable operation and good service

Focus on waste recycling and sorting technology innovation. the pursuit of comprehensive, professional, timely and enthusiastic service to win the trust of customers, growing together with customers.

MSWsorting relies on the technical team who from University of Science and Technology of China. and based on himself research and manufacturing experiences accumulated over the past 30 years. Created China's first waste sorting technology research center.