Refuse Derived Fuel (RDF)

High-energy fuel derived from various types of waste, and it offers a promising alternative to conventional fossil fuels.

What is RDF (Refuse-Derived Fuel)?

Refuse-Derived Fuel (RDF) represents a more processed and refined form of solid fuel compared to SRF. RDF refers to a standardized fuel product that undergoes advanced physical, and sometimes thermal or biological treatment, resulting in a highly homogeneous material with a specific shape (pellets, cylinders, or cubes) and superior combustion properties. Its particle size is smaller (typically <30mm), moisture content lower (typically <20%), and it possesses higher energy density and better handling characteristics. RDF is suitable for use in specially designed commercial or industrial combustion plants. It represents an advanced form of waste valorization, closer in usability to traditional fossil fuels, and is a top-tier solution for efficient waste-to-energy conversion.

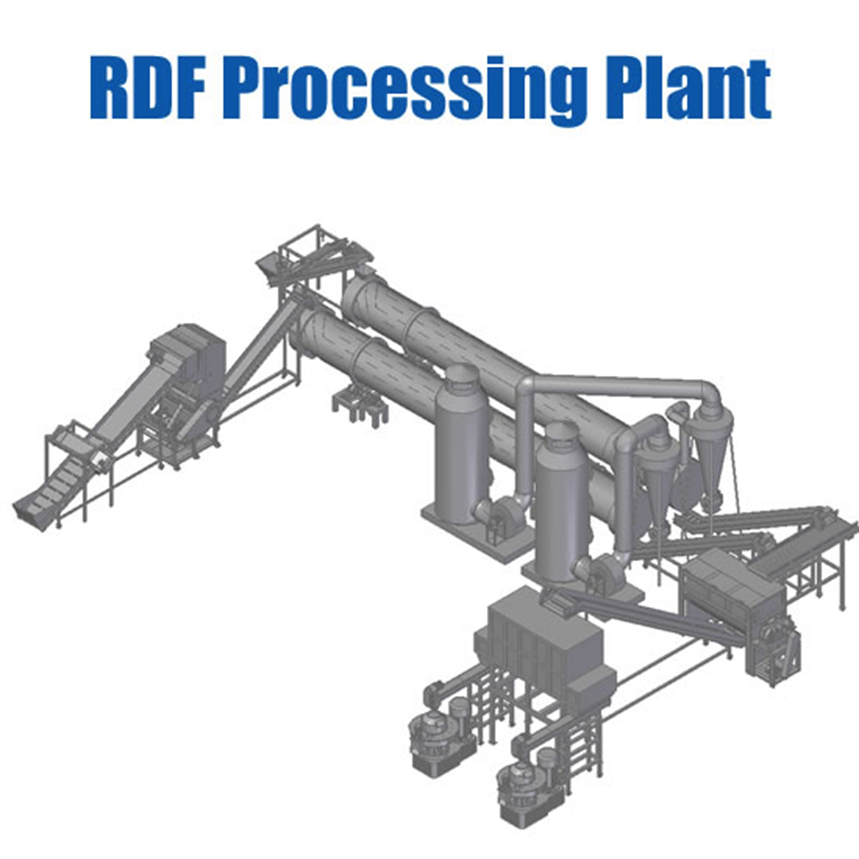

How is Waste Converted to RDF?

The production of RDF from waste is a refining and densification process that builds upon the SRF production line, adding deep processing steps:

SRF Production Stage: The process begins by following the Waste-to-SRF process to obtain shredded combustible fragments (<100mm), which serve as the raw material for RDF.

Fine Shredding: The SRF fragments are fed into a Single-Shaft Fine Shredder for further size reduction. This shredder uses high-speed rotating knives against stationary ones to grind the material into a finer, more consistent size (<30mm or finer), ideal for subsequent pelletizing.

Deep Drying (Critical Step): The finely shredded material is conveyed into an RDF-specific Dryer (rotary drum dryer, belt dryer, or bio-drying system). Using hot air (sourced from plant excess heat, gas, or some of the produced fuel), moisture is forcibly reduced from >30-40% to below 20%. This step drastically increases the net calorific value and stabilizes the material.

Pelletizing / Briquetting: The dried, low-moisture powder is fed into an RDF Pellet Mill or Briquetting Press. Under high pressure and sometimes heat, the material is extruded through a die to form dense pellets, cylinders, or cubes. This process significantly increases energy density, improves transportability and storage, and provides uniform shape and burning characteristics.

Cooling & Screening: The hot RDF pellets are cooled down in a Cooler and then passed over a Vibrating Screen to separate finished product from fines (which are recycled), ensuring final product quality.

Key Equipment and Installations for RDF Production

Single-Shaft Fine Shredder: Used for precision shredding of SRF to create the ideal particle size distribution for drying and pelletizing.

RDF Dryer: The core upgrading equipment. Typically an indirectly or directly heated rotary drum dryer that efficiently and uniformly reduces moisture, significantly enhancing net calorific value.

RDF Pellet Mill / Briquetting Press: The core densification unit. This includes Ring-Die Pellet Mills, Flat-Die Pellet Mills, or Hydraulic Briquetting Presses. They form the dried material into dense, durable fuel pellets or briquettes under high pressure.

Cooling & Screening System: A Counter-flow Cooler for cooling hot pellets and a Vibrating Screen for grading ensure uniform product size.

Upstream Support System: Includes the complete SRF preparation line equipment (Air Separator, Dual-Shaft Shredder, etc.), hot air generator, dust removal, and automated control systems.

Why Choose MSWsorting for Your RDF Project?

Producing high-quality RDF is a technology-intensive endeavor requiring exceptional process integration and control. MSWsorting is one of the few experts capable of delivering proven, reliable, and cost-effective turnkey Waste-to-RDF solutions. We deeply understand the complete technical chain from raw waste characteristics to final pellet performance. Our design is always guided by the end-user's combustion requirements, whether for a dedicated RDF power plant or as a supplementary fuel in industrial processes. Utilizing our global composition database and fuel property models, we precisely calculate the economic balance between drying energy input and calorific value gain, and optimize pellet formulation (sometimes with minimal additives to improve binding or combustion). We ensure your RDF plant operates stably and produces a premium fuel product with strong market competitiveness, achieving maximum value extraction from waste.

Waste to RDF Solutions

Our Waste-to-RDF solutions represent the pinnacle of waste-to-energy valorization:

Standard RDF Pelletizing Line: The core process is "SRF Production + Fine Shredding + Thermal Drying + Ring-Die Pelletizing." This produces cylindrical pellets with excellent market acceptance for most dedicated combustion units.

RDF Briquetting Line: For clients requiring larger fuel blocks (to replace coal in fluidized bed boilers), we provide lines centered on a Hydraulic Briquetting Press, producing high-density fuel cubes.

Modular Integration Solution: We can integrate the RDF production line as a module into existing MBT or large MRF facilities, directly upgrading sorting residues into high-value commodities, significantly enhancing the project's overall economics and resource recovery rate.

Customized Fuel Solution: Based on specific client requirements (specific calorific value, sulfur content, ash melting point), we can customize the pre-treatment intensity, drying parameters, and forming process to produce "tailor-made" specialty fuels.

ADVANTAGE

WHY CHOOSE MSWsorting

Focus on waste sorting technology more than 30 years

Research & Development

Professional waste sorting R&D team

Engineering Design

Multifarious engineering design Services

High Quality & Services

Stable operation and good service

Focus on waste recycling and sorting technology innovation. the pursuit of comprehensive, professional, timely and enthusiastic service to win the trust of customers, growing together with customers.

MSWsorting relies on the technical team who from University of Science and Technology of China. and based on himself research and manufacturing experiences accumulated over the past 30 years. Created China's first waste sorting technology research center.