Plastic Pyrolysis

LEADING WASTE SORTING AND RECYCLING EQUIPMENTS PROVIDER

Plastic Pyrolysis: Unlocking the Future of Plastic Waste Management

The Core Definition and Principle of Plastic Pyrolysis

Plastic pyrolysis is defined as the thermochemical decomposition of carbon-based polymer materials in the complete absence of oxygen. This fundamental process relies on the application of intense heat, typically between 300°C to 800°C, to systematically break the long molecular chains of plastics like polyethylene (PE) and polypropylene (PP) into smaller hydrocarbon molecules. The absence of oxygen is the critical factor that distinguishes plastic pyrolysis from incineration, preventing combustion and instead facilitating molecular rearrangement through processes such as chain scission, depolymerization, and recombination. The output of this core reaction is a spectrum of valuable products, including pyrolysis oil, synthetic gas, and a solid carbon char. The specific product slate is highly dependent on precise control of process parameters such as temperature gradient, heating rate, pressure, and residence time within the reactor.

This oxygen-free cracking process is the scientific cornerstone that enables the valorization of waste plastics. By carefully controlling temperature and residence time within a sealed reactor, the complex polymers are depolymerized into usable fractions rather than being fully oxidized. This defines plastic pyrolysis as a form of advanced or chemical recycling, aiming to recover the embedded chemical value of plastic waste as a feedstock for new production cycles. The underlying principle leverages the thermodynamic instability of polymers at high temperatures, causing random cleavage of C-C bonds and subsequent formation of free radicals. These radicals undergo various reactions—including isomerization, cyclization, and aromatization—ultimately yielding a complex mixture of hydrocarbons that can be condensed and fractionated.

Primary Methods and Technological Classifications of Plastic Pyrolysis

The field of plastic pyrolysis is characterized by several distinct technological pathways, classified mainly by heating rate, temperature, reactor design, and the strategic use of catalysts. These classifications dictate the process economics and final product distribution.

Slow Pyrolysis (Carbonization): This method operates at lower temperatures (typically 350-500°C) with very slow heating rates and long solid residence times, often extending for several hours. It is designed to maximize the yield of solid char or carbon black, producing lesser amounts of liquid and gas.

Fast Pyrolysis: Aimed at maximizing liquid bio-oil yield, fast pyrolysis employs rapid heating rates exceeding 100°C per second to a moderate temperature (~500°C) with short vapor residence times (less than 2 seconds). The vapors are then rapidly quenched to condense into a dark, viscous oil. This process requires finely ground feedstock and sophisticated heat transfer mechanisms.

Flash Pyrolysis: An even more extreme version of fast pyrolysis, with heating rates exceeding 1000°C/s, achieving very high liquid yields. It often uses specialized reactors like fluidized beds with very fine feedstock particles.

A pivotal advancement is catalytic plastic pyrolysis, which integrates specific catalysts (e.g., zeolites like ZSM-5, FCC catalysts, or basic catalysts) either in-situ within the reactor or ex-situ in a secondary upgrading stage. Catalysts serve to lower reaction energy requirements (activation energy), increase reaction rates, and critically, enhance the quality and selectivity of the oil output by promoting reactions like cracking, isomerization, and deoxygenation to yield lighter, more stable hydrocarbons in the gasoline or diesel range.

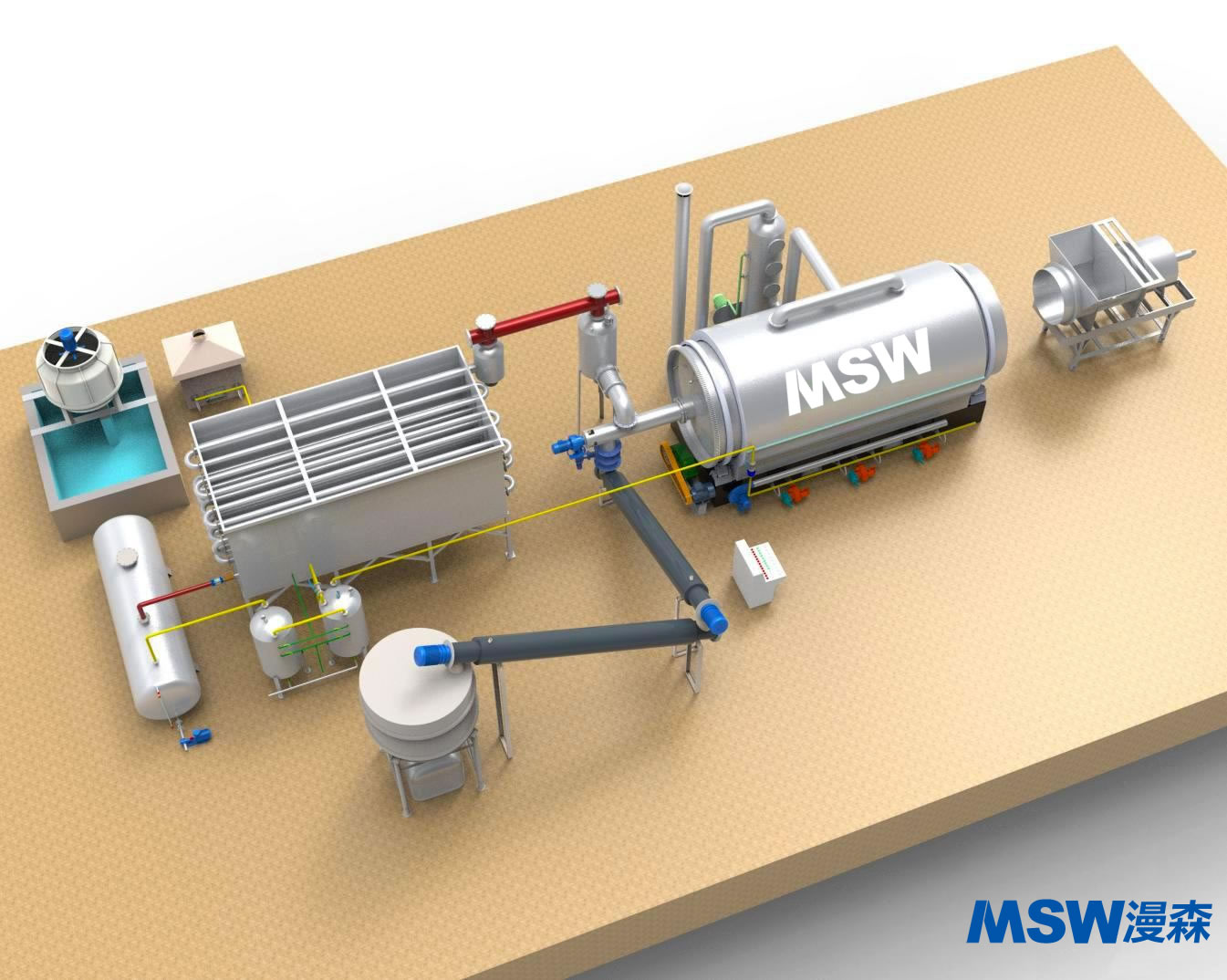

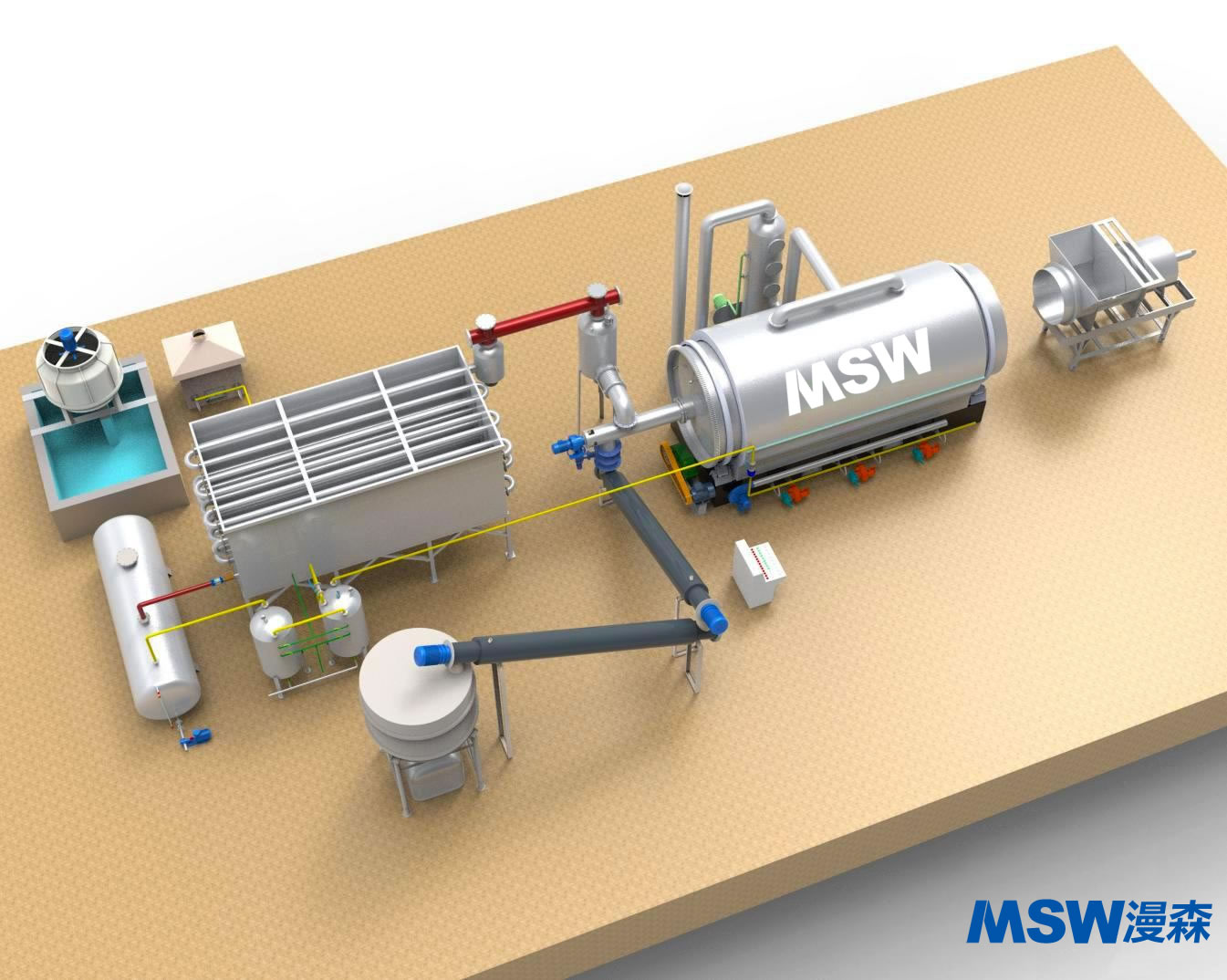

Furthermore, the choice of reactor design—such as rotary kilns, fluidized beds, ablative reactors, or screw conveyors—constitutes another essential classification, directly impacting heat transfer efficiency, feedstock handling, and process scalability for plastic pyrolysis operations. Each design has trade-offs in terms of complexity, scalability, and suitability for different plastic types and contamination levels.

Understanding these classifications is crucial for project design. For instance, a plant targeting fuel oil production from polyolefins would likely select fast pyrolysis in a fluidized bed reactor, while a facility focusing on carbon black yield from mixed waste might opt for a slower process in a rotary kiln. The integration of catalysis represents a key innovation frontier, aiming to produce drop-in ready hydrocarbons directly from the plastic pyrolysis process, thereby increasing its economic attractiveness and integration potential with existing petrochemical infrastructure.

The Environmental and Economic Advantages of Plastic Pyrolysis

The implementation of plastic pyrolysis offers a compelling dual advantage, addressing both ecological concerns and resource economics. Its benefits are multi-faceted and central to its growing appeal as a waste management solution within a circular economy framework.

Waste Diversion and Landfill Reduction: It provides a viable endpoint for complex, contaminated, or multi-layered plastic waste (such as films, laminates, and composite materials) that challenge conventional mechanical recycling. By processing these difficult streams, pyrolysis significantly reduces landfill volume, mitigates associated soil and groundwater pollution risks, and helps prevent ocean leakage from mismanaged waste.

Resource Recovery and Circular Value Chain Creation: Plastic pyrolysis transforms a waste liability into marketable commodities like fuel oil, waxes, and chemical feedstocks, establishing a new revenue stream from waste. This recaptures the energy and chemical value originally embedded in the fossil resources used to create the plastic, moving towards a closed-loop system.

Energy Independence and Process Efficiency: The non-condensable synthetic gas (syngas) produced, rich in hydrogen, methane, and carbon monoxide, can be effectively utilized to power the pyrolysis reactor itself. This internal energy recovery drastically improves the net energy balance of the plant, reducing reliance on external fossil fuels and enhancing operational sustainability.

Contributing to a Circular Carbon Economy and Reduced Carbon Footprint: By providing an alternative to virgin fossil resources for fuel and plastic production, it closes the carbon loop. Life cycle assessments often indicate a lower greenhouse gas footprint for pyrolysis-derived fuels compared to conventional fossil fuels when considering the avoided emissions from waste decomposition and virgin resource extraction. Furthermore, it reduces the demand for primary crude oil refining.

Handling of Contaminants and Additives: Unlike mechanical recycling, the high-temperature process can potentially break down or encapsulate certain organic contaminants and additives, though inorganic additives will remain in the char. This offers a potential pathway for managing plastics containing legacy additives.

Critical Challenges Facing Commercial Plastic Pyrolysis

Despite its potential, the widespread adoption of plastic pyrolysis confronts significant technical, economic, and infrastructural barriers that must be addressed for it to become a mainstream solution.

A primary technical challenge is the extreme heterogeneity and contamination of real-world plastic feedstocks collected from municipal or industrial waste streams. The presence of PVC (releasing corrosive hydrochloric acid gas), PET (which can yield oxygenated compounds), and various fillers, pigments, and flame retardants can degrade product quality, poison catalysts, cause equipment corrosion, and lead to the formation of hazardous by-products that require sophisticated gas cleaning systems. Furthermore, achieving consistent product quality from a variable feedstock requires highly adaptable and robust process control systems.

Economically, the viability of a plastic pyrolysis plant is highly sensitive to several volatile factors. The primary product, pyrolysis oil, competes directly with the fluctuating prices of crude oil; low crude prices can erase profit margins. High capital and operational costs are associated with necessary pre-treatment steps (sorting, washing, shredding), the reactors themselves, and the post-treatment of oils (hydrotreating, distillation) to meet market specifications. Securing a consistent, large-scale, and cost-effective feedstock supply chain is a non-trivial logistical challenge. The market for pyrolysis oil often requires additional hydrotreating to remove chlorine, oxygen, and other impurities and to adjust its boiling point distribution to match conventional fuels, adding significant complexity and cost.

These challenges underscore that plastic pyrolysis is not a simple plug-and-play technology. It requires a sophisticated, integrated system encompassing robust feedstock preparation, precise and adaptive process control, effective emissions management, and a viable end-market strategy. The variability of waste plastic as a feedstock is perhaps the most significant hurdle, necessitating advanced sorting and cleaning systems to ensure a consistent and suitable input for the thermochemical reaction.

Current and Emerging Outputs from Plastic Pyrolysis

The products derived from plastic pyrolysis are finding diverse applications across industries, driving its economic rationale. The yield and properties of these outputs can be tuned by adjusting process conditions.

Pyrolysis Oil (or Plastoil): The primary liquid output, a complex mixture of hydrocarbons. It is increasingly used as a heavy fuel oil substitute in industrial furnaces, cement kilns, and marine engines due to its high calorific value. With sufficient upgrading (hydrotreating and cracking), it can be refined into naphtha, diesel, or jet fuel. It also serves as a chemical feedstock for producing solvents or as a source of monomers upon further processing.

Solid Char: A carbonaceous residue containing inorganic additives (e.g., fillers, pigments) from the original plastic. It can be processed into carbon black for use as a pigment or reinforcing agent in tires, plastics, and construction materials. Research is exploring its activation to produce activated carbon for filtration applications or its use as a low-grade solid fuel.

Syngas: A mixture of non-condensable gases (H2, CO, CH4, C2-C4 gases). Its primary application is to provide the thermal energy to sustain the pyrolysis process through combustion in a burner, creating a self-sustaining operation. Surplus syngas can be cleaned and used for electricity generation in engines or turbines, or as a chemical feedstock for synthesis processes.

Perhaps most promising for a circular economy is the emerging application where purified and upgraded pyrolysis oils, particularly naphtha-range fractions, are fed into steam crackers alongside conventional naphtha to produce ethylene and propylene—the fundamental building blocks for new, virgin-quality plastics. This "plastic-to-plastic" or "feedstock recycling" pathway exemplifies the transformative promise of advanced plastic pyrolysis, moving beyond fuel production to true molecular recycling and closing the plastic loop. Additionally, the selective production of specific high-value chemicals like benzene, toluene, and xylene (BTX) from catalytic pyrolysis is an active area of research and development.

Future Innovations and the Evolving Landscape of Plastic Pyrolysis

The future trajectory of plastic pyrolysis is focused on integrated innovation to overcome existing limitations and enhance its economic and environmental performance. Research is intensely directed along several parallel paths:

Catalyst Development: Designing next-generation catalysts that are more robust to contaminants, more selective towards desired products (e.g., light olefins, BTX), and capable of operating for longer lifetimes with minimal deactivation. This includes nanostructured catalysts, multi-functional catalysts, and the use of low-cost natural catalysts.

Process Intensification and Integration: Developing more efficient reactors with superior heat and mass transfer, lower energy consumption, and the ability to handle a broader range of feedstocks. This includes microwave-assisted pyrolysis, plasma pyrolysis, and hybrid systems that combine pyrolysis with other thermal or catalytic steps in a single unit. Integration with upstream sorting (AI and robotics) and downstream refining units is key to creating efficient, large-scale value chains.

Feedstock Pre-treatment and Standardization: Innovations in automated sorting, washing, and preparation technologies are critical to produce a consistent "pyrolysis-ready" feedstock, improving process stability and product quality. The development of industry-wide standards for such feedstock could facilitate market growth.

Policy and Market Frameworks: The evolution of supportive policy frameworks will be crucial. This includes extended producer responsibility (EPR) schemes that create financial incentives for chemical recycling, recycled content mandates that recognize pyrolysis outputs, carbon pricing mechanisms, and standardized life cycle assessment (LCA) methodologies to accurately quantify environmental benefits. Integration with existing petrochemical infrastructure using a mass balance approach certified by international standards is key to scaling up and gaining market acceptance.

The synergy between improved AI-driven pre-sorting, optimized pyrolysis reactions, and advanced catalytic upgrading will define the next generation of commercial plants. Ultimately, the success of plastic pyrolysis hinges on its ability to become a reliable, cost-competitive, and environmentally sound link in the global circular economy for plastics, converting today's waste into tomorrow's resources and playing a critical role in achieving sustainable material management goals.

ADVANTAGE

WHY CHOOSE MSWsorting

Focus on waste sorting technology more than 30 years

Research & Development

Professional waste sorting R&D team

Engineering Design

Multifarious engineering design Services

High Quality & Services

Stable operation and good service

Focus on waste recycling and sorting technology innovation. the pursuit of comprehensive, professional, timely and enthusiastic service to win the trust of customers, growing together with customers.

MSWsorting relies on the technical team who from University of Science and Technology of China. and based on himself research and manufacturing experiences accumulated over the past 30 years. Created China's first waste sorting technology research center.