Solid Recovered Fuel (SRF)

LEADING WASTE SORTING AND RECYCLING EQUIPMENTS PROVIDER

What is SRF(Solid Recovered Fuel)?

Solid Recovered Fuel (SRF) is a high-quality, homogeneous, combustible material produced from the non-recyclable fractions of Municipal Solid Waste (MSW) through advanced mechanical and physical processing. It is not simply shredded trash but a standardized engineered fuel product designed to replace fossil fuels like coal in industrial energy production, such as in cement kilns, power plants, or district heating systems. Compared to raw waste, SRF features higher calorific value, more stable chemical and physical properties (size, moisture, chlorine content), and lower contaminant levels. Its core value lies in transforming non-recyclable waste destined for landfill into a valuable energy carrier, serving as a key component in "waste-to-energy" and circular economy strategies.

How is Waste Converted to SRF?

The conversion of waste to SRF is a systematic physical processing operation focused on segregating and enriching the high-calorific components of the waste stream. The principle is based on a sequence of sorting, shredding, and homogenization steps:

Pre-treatment & Sorting: Mixed MSW first enters a pre-processing line similar to a "MRF" or the mechanical stage of an MBT plant. Through bag opening, screening (trommel screen) to remove inerts and most organics, followed by magnetic and eddy current separation for metals. A critical step is air classification, which uses aerodynamic principles in a specialized Air Separator (or Wind Sifter) to segregate light, combustible "light fractions" (like plastic films, paper, textiles, wood) from heavy inert materials.

Shredding & Homogenization: The enriched high-calorific "light fraction" is fed into a Dual-Shaft Shredder for coarse shredding. This robust equipment uses powerful shearing forces to break down bulky, irregular materials into consistent fragments of a predefined size (typically <100mm), creating a relatively uniform feedstock.

Quality Enhancement & Refining: To further improve quality, the shredded material may undergo secondary air classification, optical sorting (to remove specific plastics like PVC to reduce chlorine), or fine screening to ensure compliance with specific classification standards (like EN 15359).

Storage & Transport: The final SRF output is a flaky material, often baled into large bundles or loaded into sealed containers for safe, hygienic transport to end-users.

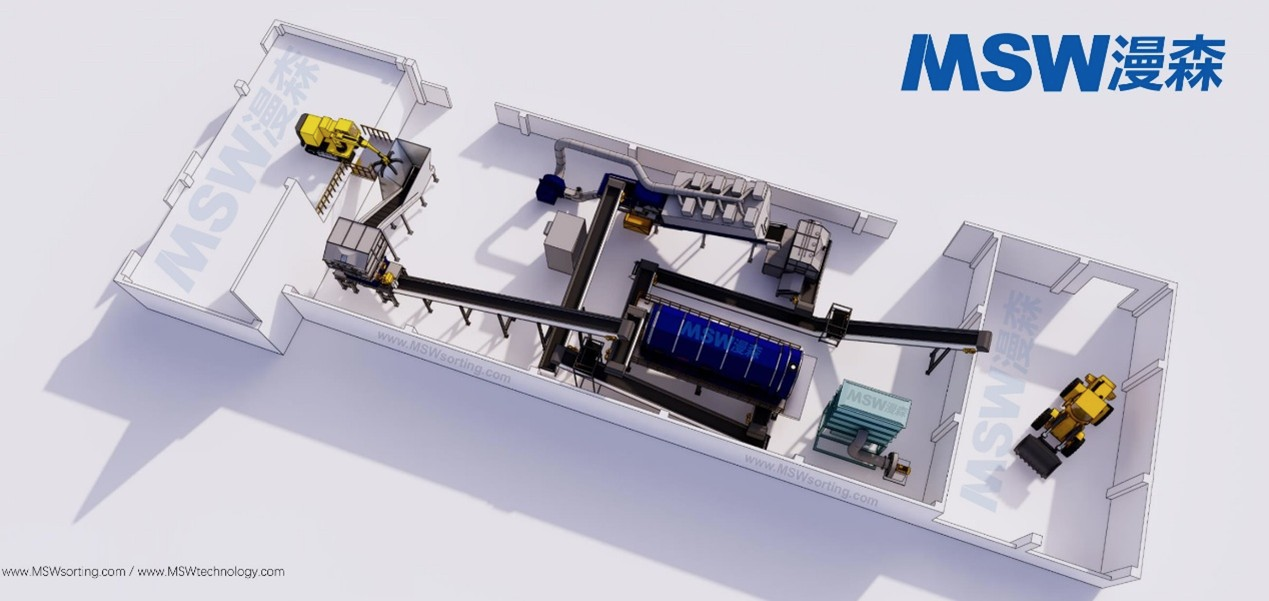

Key Equipment and Installations for SRF Production

Air Separator / Wind Sifter: The core equipment in an SRF line. It uses controlled airflow to separate light combustibles from heavy inert materials (stones, glass, residual metals) before or after shredding, significantly increasing the fuel's calorific value and purity while reducing ash content.

Dual-Shaft Shredder: A key unit for primary coarse shredding. Two counter-rotating shafts with cutting discs shred materials through shearing, tearing, and crushing. Its robust design handles mixed materials with impurities, and output size is controlled by an adjustable screen.

Fine Shredder (Optional): A single-shaft shredder or hammer mill may be used for secondary shredding to achieve greater homogeneity.

Sorting Equipment Suite: Includes Trommel Screens, Magnetic Separators, Eddy Current Separators from the pre-treatment stage, and potentially Near-Infrared (NIR) Optical Sorters for precision removal of undesired components like PVC.

Storage & Baling System: Includes storage bunkers, conveyors, and High-Density Balers to compress loose SRF into neat, manageable bales for efficient logistics and storage.

Why Choose MSWsorting for Your SRF Project?

The quality of SRF directly determines its market value and acceptability by end-users. MSWsorting provides an end-to-end solution from "waste" to "qualified commodity fuel." Our core competence stems from a profound understanding of the feedstock—leveraging our 30-year global waste composition database, we can accurately predict the proportion of combustibles, calorific potential, and contaminant levels ( chlorine, mercury) in your local waste. This allows us to design the most optimal sorting and purification process from the outset. We deliver specification-driven process engineering, ensuring the produced SRF meets or exceeds key international standards (like EN 15359) for calorific value, chlorine, and mercury content, opening access to broader, premium energy markets. We are your reliable technology partner in transforming waste liability into stable energy revenue.

Waste to SRF Solutions

Our Waste-to-SRF solutions are modular and customizable systems designed to maximize fuel recovery rates and economic returns:

Standard SRF Production Line: For most mixed waste, the core process is "Pre-treatment & Sorting + Air Classification + Dual-Shaft Shredding." This balanced solution efficiently produces SRF suitable for general industrial boiler requirements.

Premium SRF Production Line: For clients with stringent fuel quality demands (cement co-processing). This line adds Optical Sorting units for precise PVC removal and may integrate a Drying stage (bio-drying) to further reduce moisture and boost calorific value. The output is a superior-grade fuel commanding the highest market price.

Integrated MBT-SRF Solution: SRF production is integrated as a module within an MBT plant, processing the high-calorific "dry fraction" into fuel. This achieves the perfect synergy between material recycling and energy recovery, targeting near-zero landfill.

ADVANTAGE

WHY CHOOSE MSWsorting

Focus on waste sorting technology more than 30 years

Research & Development

Professional waste sorting R&D team

Engineering Design

Multifarious engineering design Services

High Quality & Services

Stable operation and good service

Focus on waste recycling and sorting technology innovation. the pursuit of comprehensive, professional, timely and enthusiastic service to win the trust of customers, growing together with customers.

MSWsorting relies on the technical team who from University of Science and Technology of China. and based on himself research and manufacturing experiences accumulated over the past 30 years. Created China's first waste sorting technology research center.