CSG1 Waste Optical Sorting Machine

By MSWsorting Systems

LEADING WASTE SORTING AND RECYCLING EQUIPMENTS PROVIDER

A Waste Optical Color Sorting Machine is a high-tech device that uses advanced sensors and light to identify and separate different types of materials based on their color. Think of it as a super-fast, super-accurate robot that can "see" the color of every single piece of waste passing by on a conveyor belt. It is a critical component in modern Material Recovery Facilities (MRFs) and recycling plants, where sorting mixed waste streams quickly and precisely is essential for efficient recycling. This technology moves beyond simply separating materials like plastic from metal; it can distinguish between different colored plastics, such as clear PET bottles from green or blue ones, which is crucial for producing high-quality recycled material.

At its core, the machine combines sophisticated optics, powerful computing, and precise mechanical actuators. It doesn't just see color in the way humans do; it can analyze the specific light spectrum reflected by an object to make incredibly detailed identifications. This allows it to perform tasks that are too tedious, dangerous, or complex for human workers, such as sorting tiny fragments of glass or identifying specific polymer types among a fast-moving stream of plastic flakes. By automating this process, optical color sorters bring a new level of purity and efficiency to the recycling industry.

Modern optical color sorters are equipped with high-resolution line-scan cameras or hyperspectral imaging sensors that capture detailed visual data from every item on the conveyor belt. These sensors are often paired with powerful LED or laser light sources that illuminate the materials consistently, ensuring accurate color detection regardless of ambient lighting conditions. The heart of the system is a high-speed computer processor running complex recognition software. This software analyzes the sensor data in real-time, comparing the color, and sometimes the material signature, of each object against pre-programmed sorting criteria to make a split-second decision.

Another defining feature is the precision ejection system. Once an unwanted or target-colored item is identified, the machine triggers a bank of high-speed, precisely timed air jets. These jets emit a brief, powerful puff of air to knock the selected item off the main conveyor belt and into a separate collection chute. The speed and coordination of this ejection are remarkable, capable of handling thousands of individual items per minute. Furthermore, these machines are highly configurable; operators can easily adjust the sorting parameters via a touchscreen interface to target different colors or materials as needed for specific waste streams.

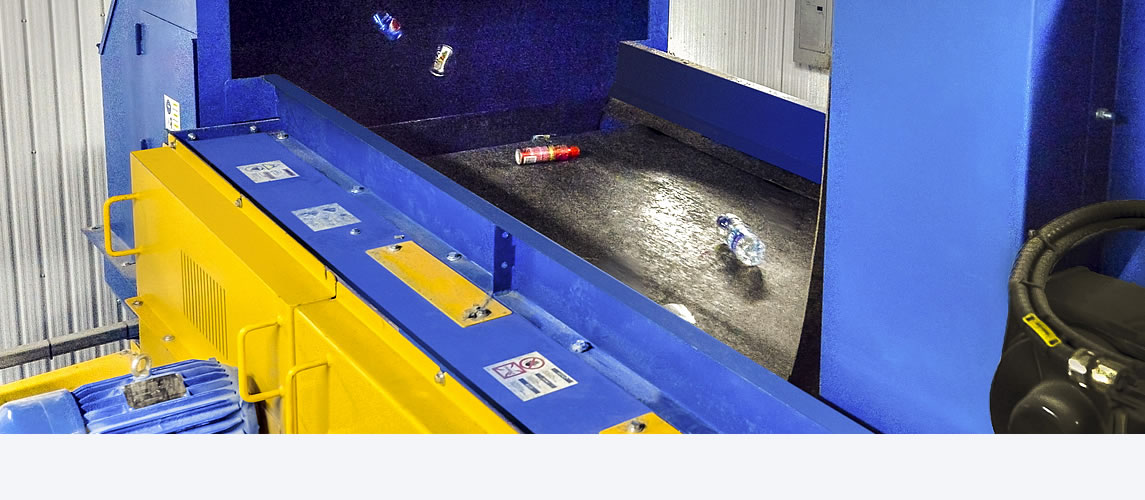

The operation of an optical color sorter is a continuous, high-speed cycle of scanning, analyzing, and ejecting. The process begins when pre-sorted waste, such as a stream of plastic flakes or glass cullet, is fed onto a high-speed vibrating conveyor or chute. This feeder spreads the material into a single, even layer so that each piece can be individually inspected. As the material flows rapidly under the inspection area, it passes over a background plate designed to provide a consistent color contrast, making it easier for the sensors to detect the target items.

In the inspection chamber, a bright, uniform light source illuminates the materials. High-speed cameras positioned above or to the side capture thousands of images per second. These images are instantly sent to the system's central processing unit. The sophisticated software analyzes each pixel, identifying objects based on their color values. When it detects a piece that matches the "accept" or "reject" criteria—for example, a brown HDPE plastic flake among clear ones—it calculates the item's exact position and trajectory. Within milliseconds, it commands a specific nozzle in the ejection array to fire a jet of compressed air, precisely deflecting the targeted piece into the correct collection bin, while the rest of the material continues on its path.

In the realm of plastic recycling, optical color sorters are indispensable. They are used to separate mixed plastic flakes by color after the plastic has been shredded and washed. For instance, they can create pure streams of clear, blue, green, or mixed-color PET or HDPE, which is essential because colored plastics, when melted down, can tint an entire batch of recycled material. Producing color-sorted, mono-material streams significantly increases the value and usability of the recycled plastic for manufacturers who need consistent, high-quality feedstock for making new bottles, containers, or polyester fiber.

Beyond plastics, this technology is widely applied in glass recycling facilities to remove ceramic contaminants (like cups and plates) and different colored glass cullet (like amber or green glass from clear flint glass). It is also used in electronic waste (e-waste) processing to sort different types of plastic components from shredded circuit boards. Furthermore, in advanced waste treatment facilities, optical sorters can help refine waste-derived fuels by removing non-combustible or undesirable materials based on their visual properties, improving the fuel's quality and burning efficiency.

The primary benefit of using optical color sorting machines is the dramatic improvement in the purity and quality of sorted recyclables. Human sorters, while valuable, cannot match the speed, consistency, or accuracy of these automated systems, especially for small or similarly shaped items. This high-purity output is critical for meeting the stringent quality standards demanded by manufacturers who use recycled content. Cleaner material streams mean less contamination, which leads to stronger, more reliable recycled products and opens up markets for higher-value applications, directly boosting the economic viability of recycling operations.

These machines also deliver substantial operational benefits, including greatly increased processing speed and throughput. They can operate continuously for 24 hours a day, significantly expanding a plant's capacity without a proportional increase in labor costs. This automation also improves workplace safety by removing employees from repetitive, dusty, and sometimes hazardous manual sorting tasks. From an environmental perspective, by enabling more efficient and higher-quality recycling, optical sorters help conserve natural resources, reduce energy consumption compared to virgin material production, and minimize the amount of waste ultimately sent to landfills.

By MSWsorting Systems

By MSWsorting Systems

By MSWsorting Systems

Belt ConveyorManual Sorting Room

For countries with low labor costs, a combination of mechanical and manual sorting can be used, which is a cost-effective waste sorting and recycling solution.

Read More

AI SortingSorting Robot

The artificial intelligence sorting robot with autonomous learning can practice and accumulate sorting data. It can effectively sort various high-value recyclables.

Read More

Optical Sorting

Optical sorter is a automatic sorting device based on sensors, high-speed ejector valve has large processing capacity. It is a good choice for bulk handling project of waste recycling.

Read More