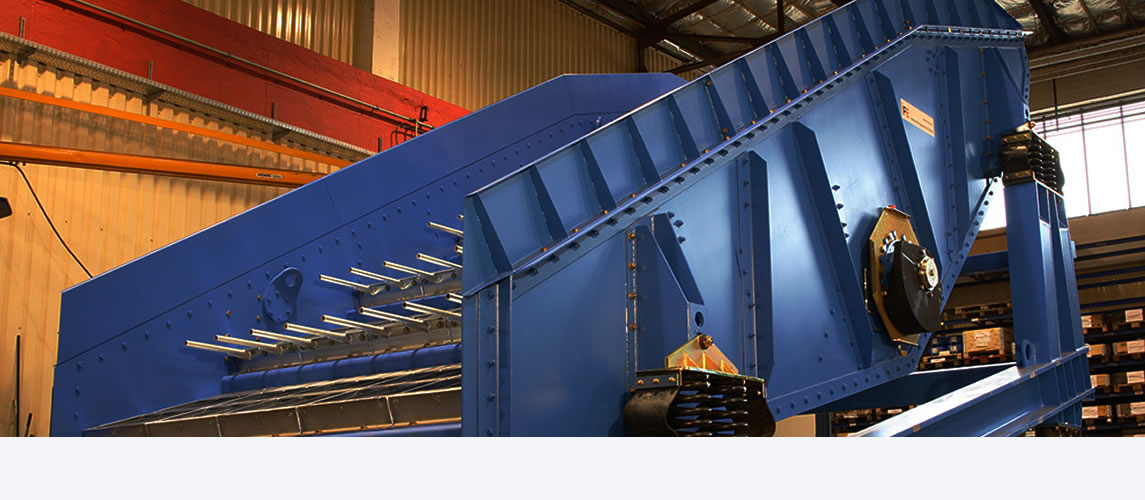

WB1 Waste Ballistic Separator

By MSWsorting Systems

LEADING WASTE SORTING AND RECYCLING EQUIPMENTS PROVIDER

A Waste Ballistic Separating Machine, often called a ballistic separator or ballistic screen, is a clever piece of equipment used in modern recycling and waste processing plants. Its main job is to sort mixed waste materials based on their shape, size, and weight, not just their size alone. Think of it like a sophisticated sifter that can tell the difference between flat, two-dimensional items like paper and cardboard, and bulky, three-dimensional items like plastic bottles and cans. This machine is a key player in Material Recovery Facilities (MRFs), helping to create cleaner streams of recyclables by separating them from general waste early in the sorting process.

The machine gets its name from the "ballistic" or throwing action it uses to separate materials. Unlike a simple mesh screen, it doesn't just let small things fall through holes. Instead, it uses a combination of paddles and a specific motion to actively propel different types of items in different directions. This makes it exceptionally good at handling the complex and often tangled mix of materials found in household and commercial waste, preparing them for more precise sorting by other machines like optical sorters or magnets.

The core feature of a ballistic separator is its rotating shaft equipped with specially shaped paddles or discs, housed inside a screened chamber or deck. As the shaft rotates, these paddles lift and throw the waste material. The machine's design and motion are calibrated so that heavy, three-dimensional objects (like containers) are carried upward and forward along the deck. In contrast, light, flat materials (like newspapers and cardboard) are carried in the opposite direction or fall through screening sections. This opposing movement effectively splits one mixed waste stream into two or three distinct categories.

Another crucial feature is its adjustability. Operators can change the speed of the rotor, the angle of the deck, and sometimes the configuration of the paddles. This allows the same machine to be tuned for different types of incoming waste or to achieve a specific separation goal. For instance, it can be set to meticulously remove all flat cardboard from a stream of packaging waste or to isolate flexible films from rigid plastics. This versatility makes it a highly valuable and adaptable component in any automated sorting line.

The operation of a ballistic separator begins when pre-shredded or loose waste is fed onto its inclined deck. The deck, which looks like a large, open trough, has a rotating shaft running through its center. Attached to this shaft are numerous paddles. As the waste lands on the deck, these paddles engage with the material. They don't just push; they scoop, lift, and then toss the items. The key to separation lies in how different items react to this tossing motion. Dense, round, or bulky items have a high inertia and tend to bounce or roll, allowing the paddles to carry them up the inclined deck.

Meanwhile, flat and flexible items like paper, magazines, and plastic bags behave differently. They don't bounce or roll easily. Instead, they tend to stay close to the deck's surface or get caught in the current created by the paddles, which carries them in the reverse direction—down the incline. Additionally, small, heavy items and fines (like dirt, glass shards, or small organic matter) can fall through gaps or screens in the deck itself, creating a third output stream. By the time the waste reaches the end of the deck, it has been neatly divided into distinct flows: one for "heavies" or 3D items, one for "flats" or 2D items, and often one for "fines."

Ballistic separators are fundamental in processing Municipal Solid Waste (MSW) and commercial recycling. In a standard Material Recovery Facility (MRF), they are often one of the first major sorting machines after initial bag breaking and rough screening. Here, they perform a critical "rough sort," separating cardboard and paper (flats) from containers like plastic bottles, metal cans, and cartons (heavies). This pre-sorting dramatically increases the efficiency of downstream equipment, such as magnets, eddy current separators, and optical sorters, which can then work on more homogeneous material streams.

Beyond traditional recycling, these machines are also vital in specialized waste processing plants. In facilities designed for Construction and Demolition (C&D) waste, ballistic separators help sort wood, plastics, and metals from rubble and fines. They are also used in composting operations to separate oversized, non-compostable materials (like plastics and metals) from the organic waste stream. Furthermore, in advanced Mechanical Biological Treatment (MBT) plants, they play a role in splitting waste into fractions for recycling, energy recovery, and biological treatment, contributing to a more circular economy.

The primary benefit of using a ballistic separator is its ability to perform a high-volume, reliable primary separation based on physical characteristics other than size. This significantly reduces the burden on subsequent, more sensitive, and often more expensive sorting technologies. By creating cleaner streams of 2D and 3D materials, it improves the purity of the final recycled products, which is essential for meeting market quality standards and achieving better economic returns. Its mechanical action is also robust and can handle wet, dirty, and inconsistent waste with less risk of jamming compared to some purely screen-based systems.

Another major advantage is operational efficiency and cost savings. The machine's high throughput capacity allows entire waste processing lines to run faster. Its adjustability means plant managers can quickly respond to changes in the composition of incoming waste without needing major mechanical changes. By automating this coarse sorting step, facilities reduce their reliance on manual labor for pre-sorting, which is often costly, inconsistent, and undesirable. This leads to a safer working environment and more predictable, efficient overall plant operation, making waste management more sustainable and economically viable.

By MSWsorting Systems

By MSWsorting Systems

By MSWsorting Systems

Belt ConveyorManual Sorting Room

For countries with low labor costs, a combination of mechanical and manual sorting can be used, which is a cost-effective waste sorting and recycling solution.

Read More

AI SortingSorting Robot

The artificial intelligence sorting robot with autonomous learning can practice and accumulate sorting data. It can effectively sort various high-value recyclables.

Read More

Optical Sorting

Optical sorter is a automatic sorting device based on sensors, high-speed ejector valve has large processing capacity. It is a good choice for bulk handling project of waste recycling.

Read More